FLAGES

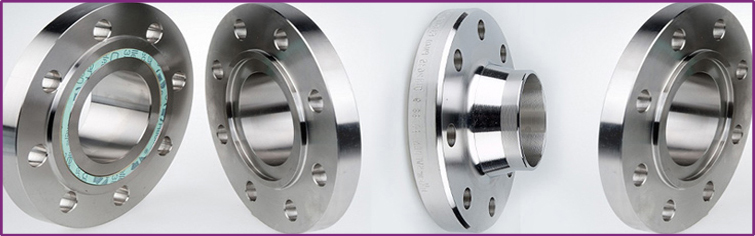

Our company supplies and export an extensive range of Forged Flanges, which is a type of pipe flanges available in various materials. These products are specially designed in such a way that the outer diameter of the pipe is slightly smaller than the diameter of the flanges. To ensure that these products comply with the industry Standards, our experienced professionals stringently check and test on various required parameters. Furthermore, we offers SORF Flanges at reasonable prices.We make use of latest techniques to manufacture a wide range of Forged Flanges. These include Weld Neck Flange, Slip on Flange, Socket Welding Flange, Lap Joint Flange and Threaded Flange.

Stainless Steel Flanges | |||||||

Sr. No. | Material | Size | Class | Specification | Items | ||

1 | Forged Flanges | 15 NB to 750 NB | 150# 300# 600# | 900# 1500# | A-182 ANSI B16.5 | SORF WNRF BLRF SWRF | LAP Joint Threaded Reducing |

2 | Plate Flanges | 15 NB to 500 NB | ASA 150 Table D Table E DIN Table ND-6 ND-10 | ASA 300 Table F Table H ND-16 ND-25 ND-40 | A-240, ANSI B16.5 | SORF BLRF | LAP Joint & Spectacle |

| Note:- | ||||||

| Grade | 304 304L 304H 316 | 316L 316LN 316Ti 309 | 310S 317L 321 347 | 410 420 440C 202 Etc. | ||

| Test Certificate | Manufacturer Test Certificate Under Third Party Inspection | |||||

| Specialize | As Per Drawing | |||||

Carbon Steel Flanges | |||||||

Sr. No. | Material | Size | Class | Specification | Items | ||

1 | Forged Flanges | 15 NB to 750 NB | 150 300 600 | 900 & 1500 LBS | A-105 ANSI B16.5 | SORF WNRF BLRF SWRF | LAP Joint Threaded Reducing |

2 | Plate Flanges | 15 NB to 500 NB | ASA 150 ASA 300 Table ‘D’ Table ‘E’ Table ‘F’ Table ‘H’ | DIN Table ND-6 ND-10 ND-16 ND-25 ND-40 | A-516, Gr.60/70 IS 2062 ANSI B16.5 | SORF BLRF | LAP Joint & Spectacle |

| Note:- | |

| Other Grade Available | A-350 LF2 |

| Test Certificate | Manufacturer Test Certificate IBR Test Certificate (Form III-C) Under Third Party Inspection |

| Specialize | As Per Drawing IBR Flanges |

Nickel Alloy Flanges | |||||

Sr. No. | Material | Size | Class | Specification | Items |

1 | Cupro Nickel Hastelloy Nickel Monel Inconel Alloy 20 Duplex | 15 NB to 200 NB | 150# 300# | ASTM BS DIN | SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing |

ASA 150, 300 Table D, E, F, H, DIN, ND-6, 10, 16, 25, 40 | SORF, BLRF, LAP Joint Etc. | ||||

| Note:- | |

| Grade | Cupro Nickel (90/10, 70/30, 66/30/2/2) Hastelloy (C-4, C-22, C276, B-2) Nickel (200 / 201 / 205) Monel (400 & K500) Inconel (600, 601, 625 & 825) Incolloy (800, 800H) Alloy 20 Duplex Steel SS 904L Titanium (1 & 2) Etc. |

| Test Certificate | Manufacturer Test Certificate Under Third Party Inspection |

BLIND FLANGES

The Blind Flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This blind flange is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles. This flange helps in easy access to a line once it has been sealed. The blind flange is sometimes custom made or machined to accept a nominal sized pipe to which reduction is being made. This reduction can be a threaded reduction or welded reduction.

Blind Flanges Product Range

Range : ½” (15 NB) to 48″ (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. Available with NACE MR 01-75

Stainless Steel Blind Flanges

Grade : 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430L

Duplex Steel Blind Flanges

Grade : 2205 (UNS No. S31803), 2507 (UNS No. S32750)

Nickel Alloy Blind Flanges

Grade : Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Copper Alloy Blind Flanges

Grade : UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

Variations:

Face finish : Raised face (RF) – Flat face (FF) – RTJ – …

Variations : Spectacle Blind

Standards:

ASTM A182 – ASME SA182 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’

ASME B16.5 – ‘Pipe Flanges and Flanged Fittings’

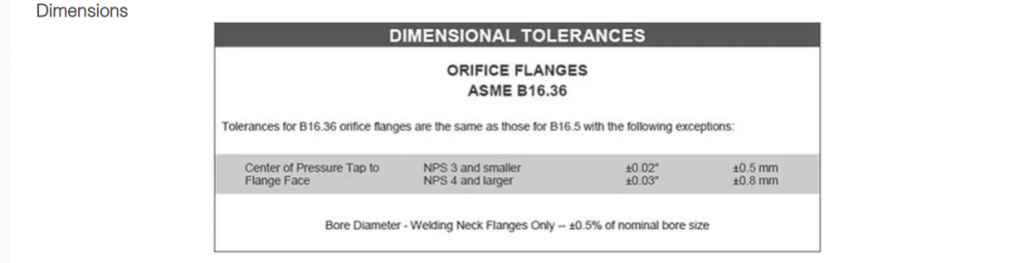

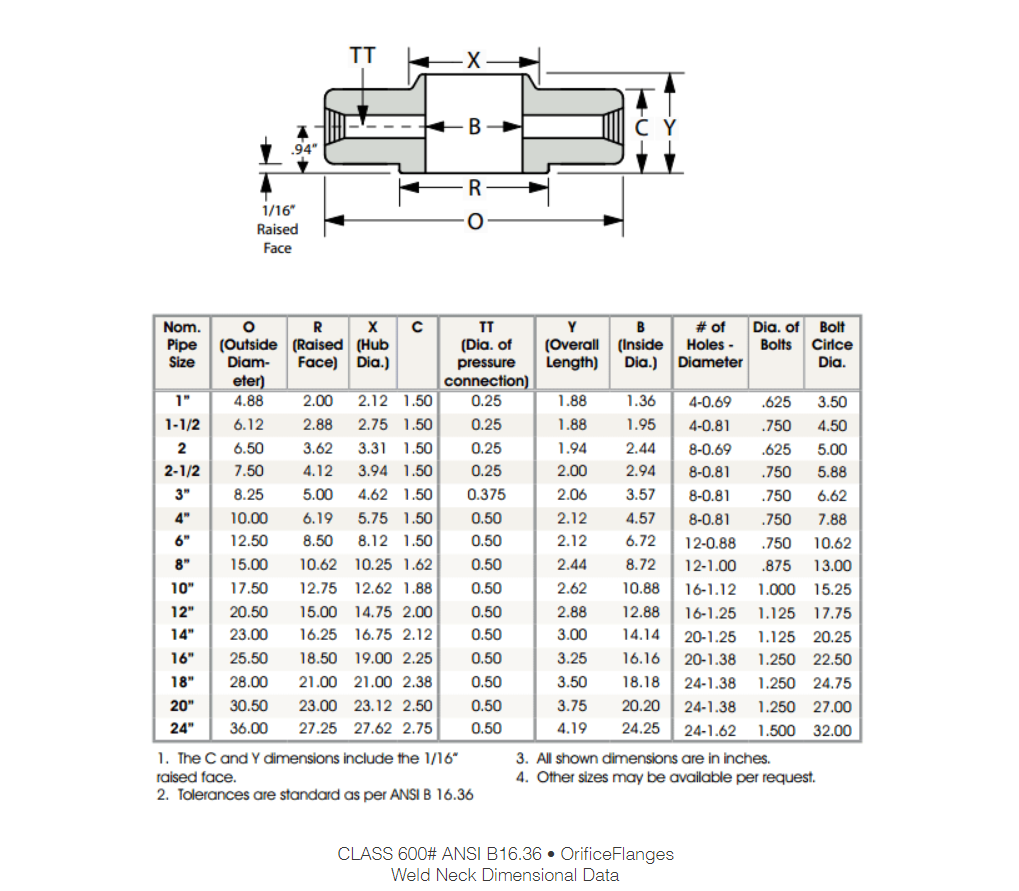

ASME B16.36 – ‘Orifice Flanges’

ASME B16.47 – ‘Large Diameter Steel Flanges NPS26 Through NPS60’

MSS SP-6 – ‘Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings’

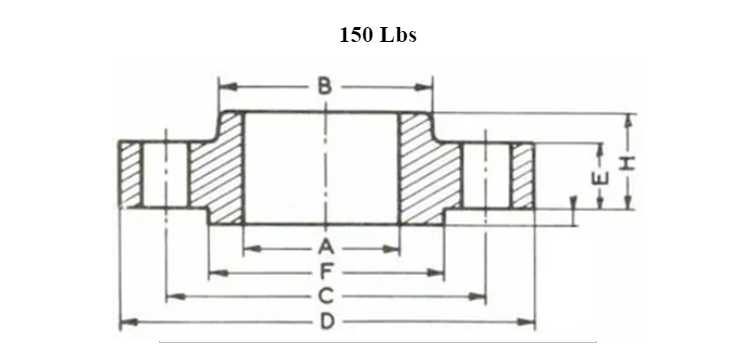

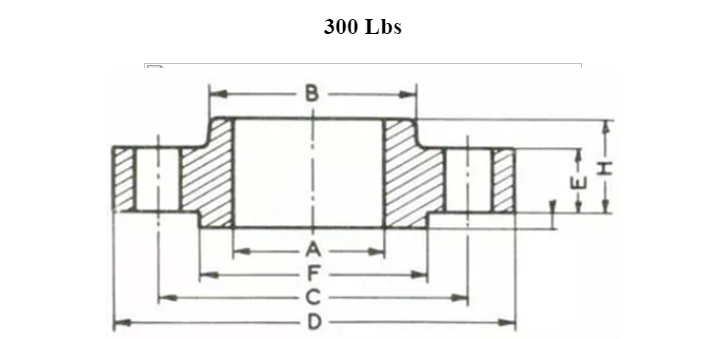

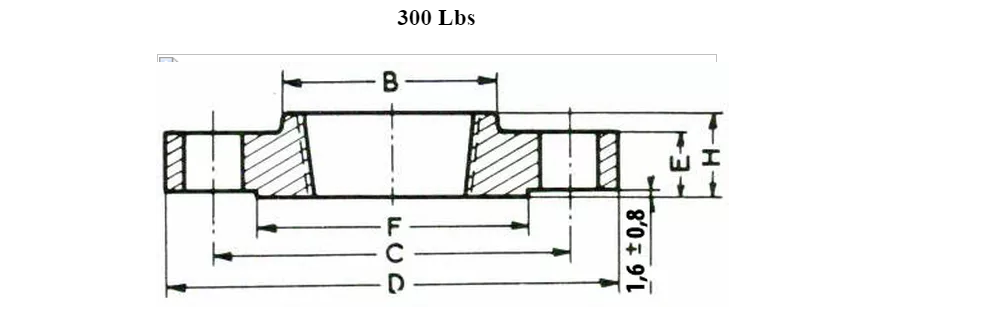

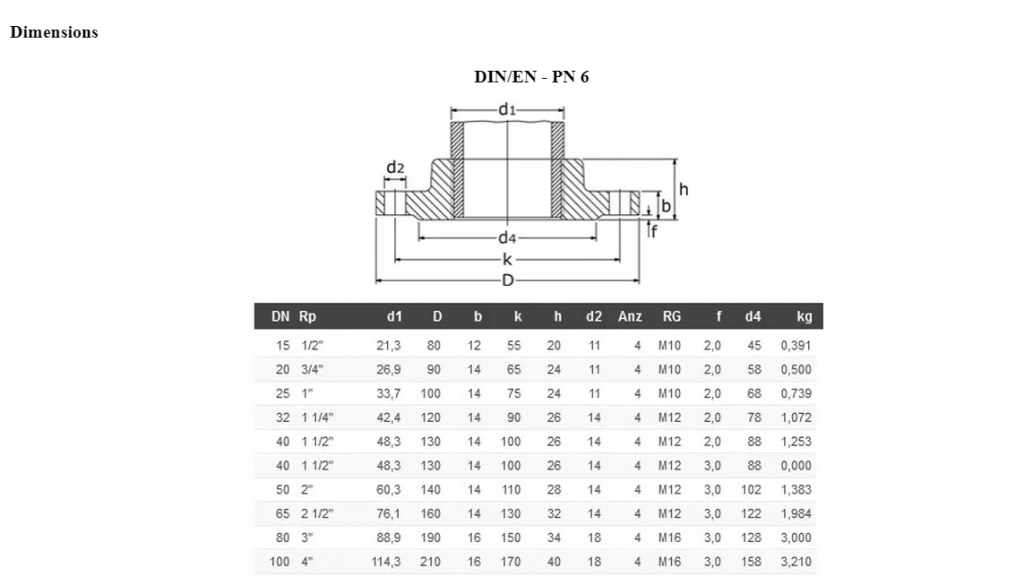

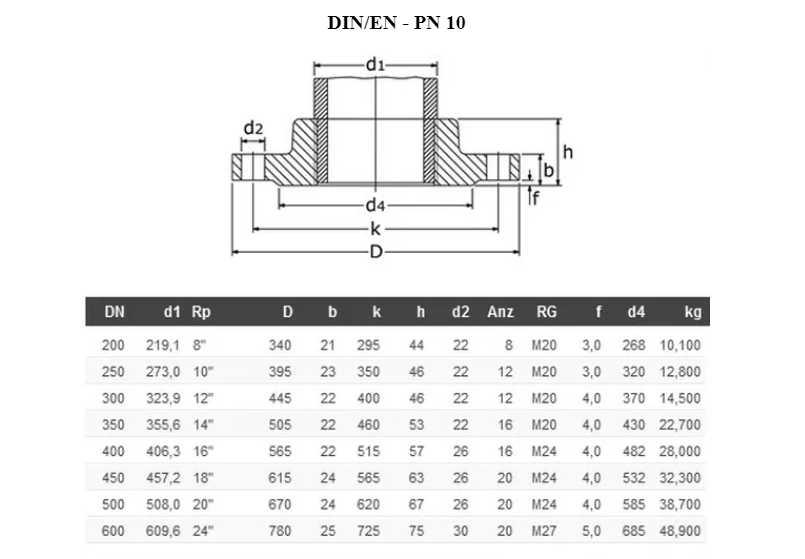

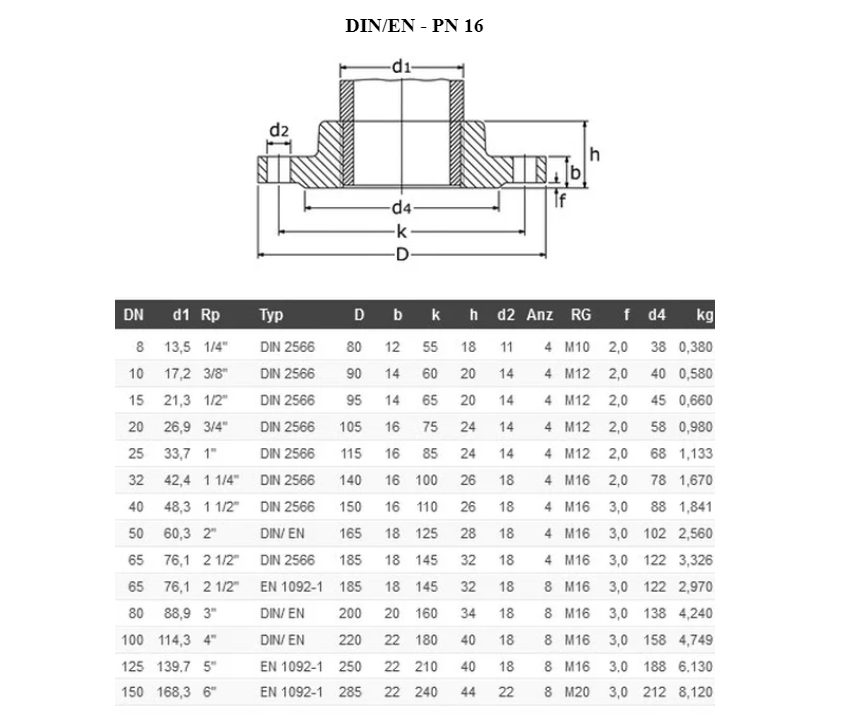

Dimensions

Diameter : 1/2″ à 24″

Pressure class : 150# – 300# – 600# – 1500#

Grades : F304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS S32750

Class: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500

Features of blind flanges:

Some important features of blind flanges are as follows:

Blind flanges are sometimes supplied with NPT fittings which allow pressure test connections to be fitted.

They are used to blank off the ends of pipe.

They are also used to blank off the ends of valves and pressure vessel opening.

Considering factors like internal pressure and bolt loading, blind flanges, especially in the larger sizes, are the most highly stressed of all types of flanges.

Since the maximum stresses in a blind flange are bending stresses at the center, they can safely be allowed to be higher than in other types of flanges

Blind flanges are made to fit standard pipes in all sizes..

Notes :

Flange dimensions to ANSI to B16.5.

Dimensions “D” includes raised face thickness.

Larger outlet sizes available on applications.

ANSI 150# / 300# 2mm Raised Face.

ANSI 600# / 2500# 7mm Raised Face.

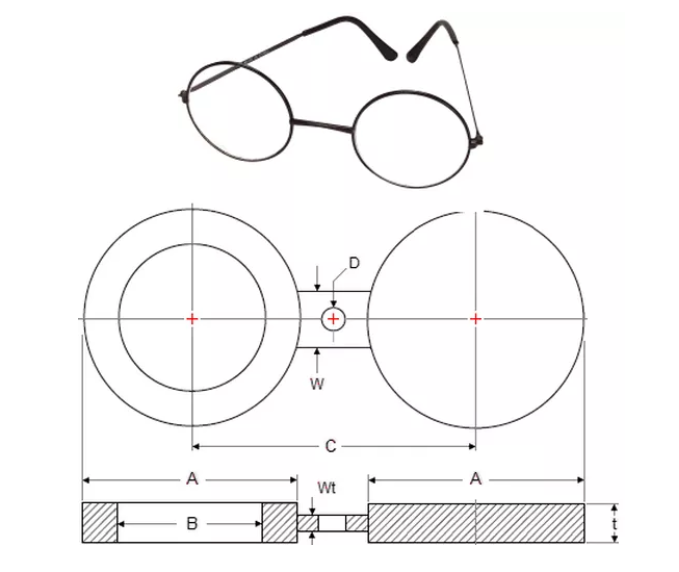

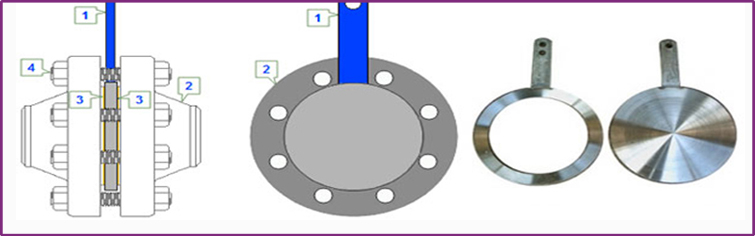

SPECTACLE BLIND

Our product range also comprises of Carbon Steel Flanges, Spectacle Flange and Duplex Flanges.These are durable in quality and are precision made. These spectacle flanges are made from high quality carbon steel and stainless steel and are offered in different dimensions & sizes that ensure that no compromise is made the aspect of quality.

Spectacle Flanges Range

½” (15 NB) to 48″ (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. Available with NACE MR 01-75

Stainless Steel Spectacle Flanges

Grade : 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430L

Duplex Steel Spectacle Flanges

Grade : 2205 (UNS No. S31803), 2507 (UNS No. S32750)

Nickel Alloy Spectacle Flanges

Grade : Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Copper Alloy Spectacle Flanges

Grade : UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

Dimensions :

Spectacle Flanges Standard

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10

OTHER : PLATE, PLATE BLANK

Spectacle Blinds Flanges ANSI B16.5 Class 150 Flanges

ANSI flanges are available at Steel Tubes India Flange in class 150. The ANSI flanges in the class 150 specification cover slip-ons, weld necks, lap joints, blinds, threaded and socket weld flanges. ANSI flanges for class 150 are provided by Steel Tubes India Flange as forgings unless otherwise specified.

CLASS 150 SPECTACLE BLINDS

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

| 1/2 | 45 | 16 | 60 | 3 | 38 |

| 3/4 | 54 | 21 | 70 | 3 | 38 |

| 1 | 64 | 27 | 80 | 3 | 38 |

| 1¼ | 73 | 42 | 90 | 6.4 | 38 |

| 1½ | 83 | 48 | 100 | 6.4 | 38 |

| 2 | 102 | 61 | 120 | 6.4 | 51 |

| 2½ | 107 | 73 | 140 | 6.4 | 51 |

| 3 | 133 | 89 | 150 | 6.4 | 64 |

| 3½ | 159 | 102 | 175 | 9.7 | 64 |

| 4 | 172 | 114 | 190 | 9.7 | 64 |

| 5 | 194 | 141 | 215 | 9.7 | 76 |

| 6 | 219 | 168 | 240 | 12.7 | 76 |

| 8 | 276 | 219 | 300 | 12.7 | 76 |

| 10 | 337 | 273 | 360 | 15.7 | 102 |

| 12 | 406 | 324 | 430 | 19.1 | 102 |

| 14 | 448 | 356 | 475 | 19.1 | 108 |

| 16 | 511 | 406 | 460 | 22.4 | 108 |

| 18 | 546 | 457 | 580 | 25.4 | 114 |

| 20 | 603 | 508 | 635 | 28.4 | 121 |

| 24 | 714 | 610 | 750 | 31.8 | 140 |

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

Spectacle Blinds Flanges ANSI B16.5 Class 300 Flanges

ANSI flanges are available at Steel Tubes India Flange in class 300. The ANSI flanges in the class 300 specification cover slip-ons, weld necks, lap joints, blinds, threaded and socket weld flanges. ANSI flanges for class 300 are provided by Steel Tubes India Flange as forgings unless otherwise specified.

ClASS 300 SPECTACLE BLINDS

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 38 |

| 1¼ | 79 | 42 | 100 | 6.4 | 38 |

| 1½ | 92 | 48 | 115 | 6.4 | 38 |

| 2 | 108 | 61 | 125 | 9.7 | 51 |

| 2½ | 127 | 73 | 150 | 9.7 | 51 |

| 3 | 146 | 89 | 170 | 9.7 | 64 |

| 3½ | 162 | 102 | 185 | 12.7 | 64 |

| 4 | 178 | 114 | 200 | 12.7 | 64 |

| 5 | 213 | 141 | 235 | 15.7 | 76 |

| 6 | 248 | 168 | 270 | 15.7 | 76 |

| 8 | 305 | 219 | 330 | 22.4 | 76 |

| 10 | 359 | 273 | 385 | 25.4 | 102 |

| 12 | 419 | 324 | 450 | 28.4 | 102 |

| 14 | 483 | 356 | 515 | 31.8 | 108 |

| 16 | 536 | 406 | 570 | 38.1 | 108 |

| 18 | 594 | 457 | 630 | 41.1 | 114 |

| 20 | 651 | 508 | 685 | 44.5 | 121 |

| 24 | 772 | 610 | 810 | 50.8 | 140 |

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

Spectacle Blinds Flanges ANSI B16.5 Class 400 Flanges

ANSI flanges are available at Steel Tubes India Flange in class 400. The ANSI flanges in the class 400 specification cover slip-ons, weld necks, lap joints, blinds, and threaded flanges. ANSI flanges for class 400 are provided by Steel Tubes India Flange as forgings unless otherwise specified.

Spectacle Blinds Flanges ANSI B16.5 Class 600 Flanges

ANSI flanges are available at Steel Tubes India Flange in class 600. The ANSI flanges in the class 600 specification cover slip-ons, weld necks, lap joints, blinds, threaded and socket weld flanges. ANSI flanges for class 600 are provided by Steel Tubes India Flange as forgings unless otherwise specified.

CLASS 600 SPECTACLE BLINDS

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 57 |

| 1¼ | 79 | 37 | 100 | 9.7 | 57 |

| 1½ | 92 | 43 | 115 | 9.7 | 67 |

| 2 | 108 | 55 | 125 | 9.7 | 57 |

| 2½ | 127 | 67 | 150 | 12.7 | 67 |

| 3 | 146 | 83 | 170 | 12.7 | 67 |

| 3½ | 159 | 96 | 185 | 15.7 | 76 |

| 4 | 191 | 108 | 215 | 15.7 | 76 |

| 5 | 238 | 135 | 265 | 19.1 | 86 |

| 6 | 264 | 162 | 290 | 22.4 | 86 |

| 8 | 318 | 212 | 350 | 28.4 | 95 |

| 10 | 397 | 265 | 430 | 35.1 | 105 |

| 12 | 454 | 315 | 490 | 41.1 | 105 |

| 14 | 489 | 346 | 525 | 44.5 | 114 |

| 16 | 562 | 397 | 605 | 50.8 | 124 |

| 18 | 610 | 448 | 655 | 53.8 | 133 |

| 20 | 679 | 497 | 725 | 63.5 | 133 |

| 24 | 787 | 597 | 840 | 73.2 | 152 |

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

Spectacle Blinds Flanges ANSI B16.5 Class 900 Flanges

ANSI flanges are available at Steel Tubes India Flange in class 900. The ANSI flanges in the class 900 specification cover slip-ons, weld necks, lap joints, blinds, threaded and socket weld flanges. ANSI flanges for class 900 are provided by Steel Tubes India Flange as forgings unless otherwise specified.

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

| 1/2 | 60 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 6.4 | 41 |

| 1 | 76 | 27 | 100 | 6.4 | 57 |

| 1¼ | 86 | 37 | 110 | 9.7 | 57 |

| 1½ | 95 | 43 | 125 | 9.7 | 67 |

| 2 | 140 | 55 | 165 | 12.7 | 57 |

| 2½ | 162 | 67 | 190 | 12.7 | 67 |

| 3 | 165 | 83 | 190 | 15.7 | 67 |

| 4 | 203 | 108 | 235 | 19.1 | 76 |

| 5 | 244 | 135 | 280 | 22.4 | 86 |

| 6 | 286 | 162 | 320 | 25.4 | 86 |

| 8 | 356 | 212 | 395 | 35.1 | 95 |

| 10 | 432 | 265 | 470 | 41.1 | 105 |

| 12 | 495 | 315 | 535 | 47.8 | 105 |

| 14 | 518 | 346 | 560 | 53.8 | 114 |

| 16 | 572 | 397 | 615 | 60.5 | 124 |

| 18 | 635 | 448 | 685 | 66.5 | 133 |

| 20 | 696 | 497 | 750 | 73.2 | 133 |

| 24 | 835 | 597 | 900 | 88.9 | 152 |

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

Spectacle Blinds Flanges ANSI B16.5 Class 1500 Flanges

ANSI flanges are available at Steel Tubes India Flange in class 1500. The ANSI flanges in the class 1500 specification cover slip-ons, weld necks, lap joints, blinds, threaded and socket weld flanges. ANSI flanges for class 1500 are provided by Steel Tubes India Flange as forgings unless otherwise specified.

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

| 1/2 | 61 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 9.7 | 41 |

| 1 | 76 | 27 | 100 | 9.7 | 64 |

| 1¼ | 86 | 35 | 110 | 9.7 | 64 |

| 1½ | 95 | 41 | 125 | 12.7 | 70 |

| 2 | 140 | 53 | 165 | 12.7 | 70 |

| 2½ | 162 | 63 | 190 | 15.7 | 76 |

| 3 | 172 | 78 | 205 | 19.1 | 76 |

| 4 | 206 | 102 | 240 | 22.4 | 89 |

| 5 | 251 | 128 | 290 | 28.4 | 89 |

| 6 | 279 | 154 | 320 | 35.1 | 89 |

| 8 | 349 | 203 | 395 | 41.1 | 102 |

| 10 | 432 | 255 | 480 | 50.8 | 114 |

| 12 | 518 | 303 | 570 | 60.5 | 114 |

| 14 | 575 | 333 | 635 | 66.5 | 127 |

| 16 | 638 | 381 | 705 | 76.2 | 133 |

| 18 | 702 | 429 | 775 | 85.9 | 146 |

| 20 | 752 | 478 | 830 | 95.3 | 152 |

| 24 | 899 | 575 | 990 | 111.3 | 178 |

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

Spectacle Blinds Flanges ANSI B16.5 Class 2500 Flanges

ANSI flanges are available at Steel Tubes India Flange in class 2500. The ANSI flanges in the class 2500 specification cover slip-ons, weld necks, lap joints, blinds, and threaded flanges. ANSI flanges for class 2500 are provided by Steel Tubes India Flange as forgings unless otherwise specified.

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

| 1/2 | 67 | 16 | 90 | 9.7 | 38 |

| 3/4 | 73 | 21 | 95 | 9.7 | 41 |

| 1 | 83 | 27 | 110 | 9.7 | 64 |

| 1¼ | 102 | 35 | 130 | 12.7 | 64 |

| 1½ | 114 | 41 | 145 | 15.7 | 70 |

| 2 | 143 | 53 | 170 | 15.7 | 70 |

| 2½ | 165 | 63 | 195 | 19.1 | 76 |

| 3 | 194 | 78 | 230 | 22.4 | 76 |

| 4 | 232 | 102 | 275 | 28.4 | 89 |

| 5 | 276 | 128 | 325 | 35.1 | 89 |

| 6 | 314 | 154 | 370 | 41.1 | 89 |

| 8 | 384 | 198 | 440 | 53.8 | 102 |

| 10 | 473 | 248 | 540 | 66.5 | 114 |

| 12 | 546 | 289 | 620 | 79.2 | 114 |

| NPS | Outside Ø A | Inside Ø B | Centerline C | Thickness t | Web Width W |

General notes:

Dimensions are in millimeters unless otherwise indicated.

D = Hole size (where required) should be the same as the flange bolt hole. In practice, these dimensions have been rounded round off upwards.

Wt = Thickness of the web (or tie bar) should be 6 mm minimum, or equal to Thickness (t) if less than 6 mm.

Spectacle Blinds Flanges should be made from a plate or forging specification, approved for use by ASME B31.3, of essentially the same chemical composition as the mating flanges and piping involved.

Spectacle Blinds Flanges according to ASME B16.48 may be used for installation between ASME B16.5 flanges

Depending on a customer specification, some dimensions can be different from what on this page is defined.

HIGH HUB BLIND FLANGES

The high hub blind flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This high hub blind flange is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles. This flange helps in easy access to a line once it has been sealed. The high hub blind flange is sometimes custom made or machined to accept a nominal sized pipe to which reduction is being made. This reduction can be a threaded reduction or welded reduction.

Dimensions

Class 150 HH High Hub Blind Flanges

| Item ID | Class 150 HH High Hub Blind Flanges Description |

| 1FF .51RHHBLD | 1/2 150 RF HIGH HUB BLIND ASME B16.5 001 lbs |

| 1FF .751RHHBL | 3/4 150 RF HIGH HUB BLIND ASME B16.5 002 lbs |

| 1FF 11RHHBL | 1 150 RF HIGH HUB BLIND ASME B16.5 002 lbs |

| 1FF 1.51RHHBL | 1 1/2 150 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF 21RHHBL | 2 150 RF HIGH HUB BLIND ASME B16.5 005 lbs |

| 1FF 31RHHBL | 3 150 RF HIGH HUB BLIND ASME B16.5 009 lbs |

| 1FF 41RHHBL | 4 150 RF HIGH HUB BLIND ASME B16.5 017 lbs |

Class 300 HH High Hub Blind Flanges

| Item ID | Class 300 HH High Hub Blind Flanges Description |

| 1FF .53RHHBL | 1/2 300 RF HIGH HUB BLIND ASME B16.5 002 lbs |

| 1FF .753RHHBL | 3/4 300 RF HIGH HUB BLIND ASME B16.5 003 lbs |

| 1FF 13RHHBL | 1 300 RF HIGH HUB BLIND ASME B16.5 003 lbs |

| 1FF 1.53RHHBL | 1 1/2 300 RF HIGH HUB BLIND ASME B16.5 006 lbs |

| 1FF 23RHHBL | 2 300 RF HIGH HUB BLIND ASME B16.5 008 lbs |

Class 600 HH High Hub Blind Flanges

| Item ID | Class 600 HH High Hub Blind Flanges Description |

| 1FF .756RHHBL | 3/4 600 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF .56RHHBL | 1/2 600 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF 16RHHBL | 1 600 RF HIGH HUB BLIND ASME B16.5 004 lbs |

| 1FF 1.56RHHBL | 1 1/2 600 RF HIGH HUB BLIND ASME B16.5 008 lbs |

| 1FF 26RHHBL | 2 600 RF HIGH HUB BLIND ASME B16.5 010 lbs |

Copper Alloy High Hub Blind Flanges

ASTM / ASME SB 61 / 62 / 151 / 152.

C 70600 (CU -NI- 90/10) – Cupro Nickel High Hub Blind Flanges

C 71500 (CU -NI- 70/30) – Copper Nickel High Hub Blind Flanges

UNS NO. C 92200, UNS NO. C 83600, UNS NO. UNS NO C 10100,

C 10200, C 10300, C 10800, C 12000, C 12200

Duplex Steel High Hub Blind Flanges

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Alloy Steel High Hub Blind Flanges – AS High Hub Blind Flanges

ASTM SA 182 F1/F5/F9/F11/F22/F91

Carbon Steel High Hub Blind Flanges – CS High Hub Blind Flanges

ASTMA 105 Gr. F42/46/52/56/60/65/70

Low Temperature Carbon Steel High Hub Blind Flanges – LTCS High Hub Blind Flanges

A350 LF2/A350 LF3

Value Added Services

• Hot Dip Galvanizing • Electro polish

Test Certificate

Mill Test Certificate as per EN 10204 / 3.1B

Duplex Stainless Steel : Duplex Stainless Steel High Hub Blind Flanges – Duplex SS High Hub Blind Flanges

ASTM A 182 – High Hub Blind Flanges

F 51 UNS S31803 High Hub Blind Flanges

S32750 High Hub Blind Flanges

S31500 High Hub Blind Flanges

ASTM / ASME A/SA 182 UNS High Hub Blind Flanges

F 44 High Hub Blind Flanges

F 45 High Hub Blind Flanges

F51 High Hub Blind Flanges

F 53 High Hub Blind Flanges

F 55 High Hub Blind Flanges

F 60 High Hub Blind Flanges

F 61 High Hub Blind Flanges

Carbon Steel High Hub Blind Flanges – CS High Hub Blind Flanges

ASTM A105 High Hub Blind Flanges

ASTM A 694-F42 High Hub Blind Flanges

F46 High Hub Blind Flanges

F52 High Hub Blind Flanges

F60 High Hub Blind Flanges

F65 High Hub Blind Flanges

F70 High Hub Blind Flanges

Copper Nickel High Hub Blind Flanges – Cu-Ni High Hub Blind Flanges.

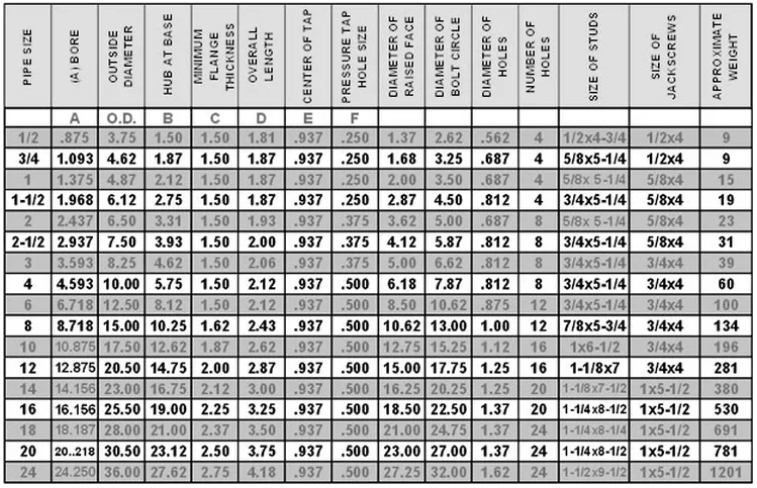

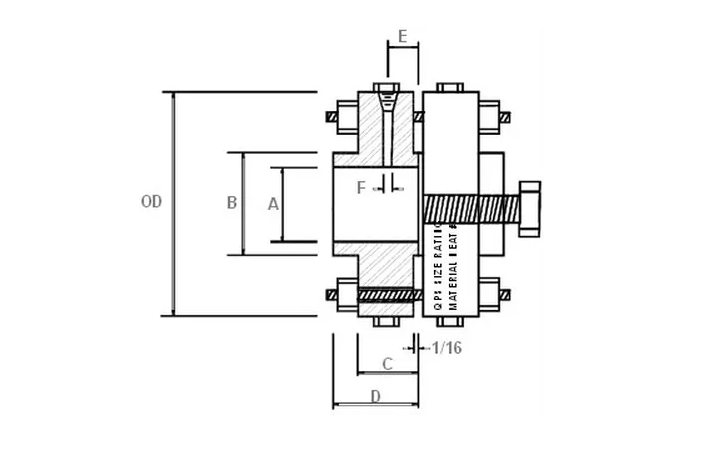

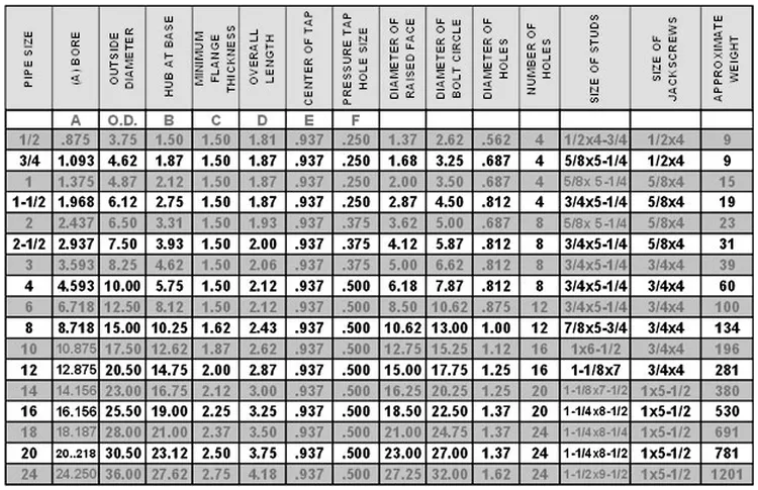

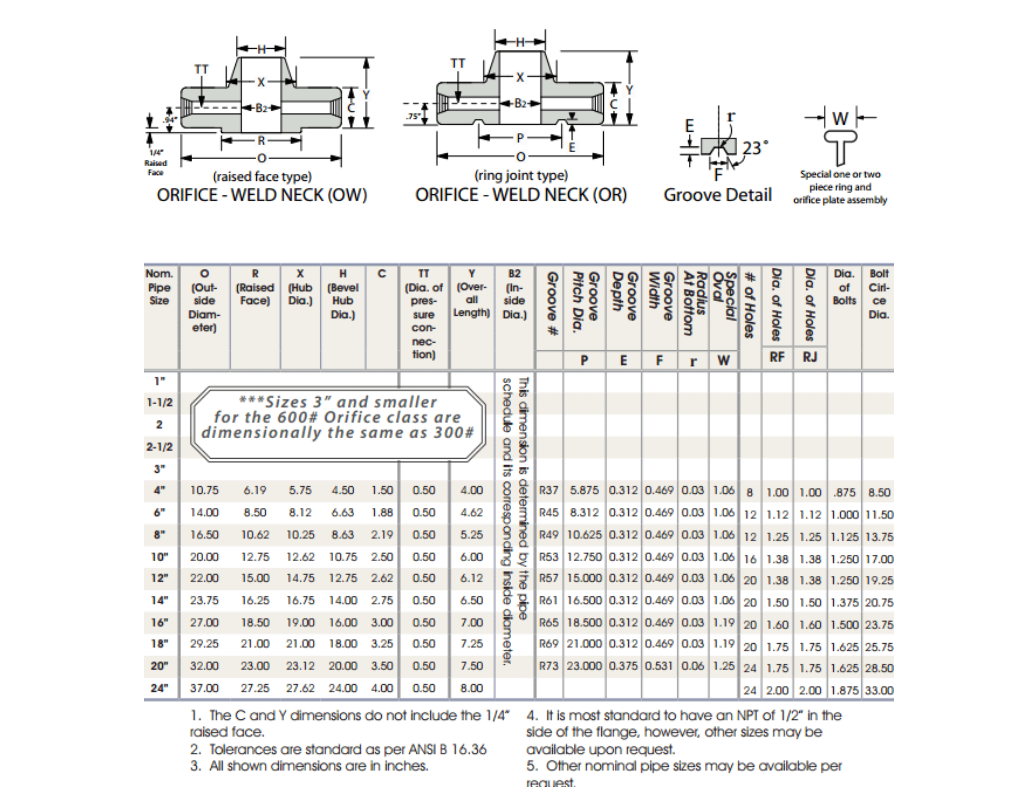

ORIFICE FLANGES

ORIFICE FLANGES are widely used in conjunction with orifice meters for measuring the rate of flow of liquids and gases. They are basically the same as standard welding neck and slip-on flanges except for the provision of radial, tapped holes in the flange ring for meter connections and additional bolts to act as jack screws to facilitate separating the flanges for inspection or replacement of the orifice plate. In choosing the type of orifice flange, the considerations affecting the choice of welding neck and slip-on standard flanges apply with equal force.

MATERIALS: A105 (C.S.) AND A182 (S.S.)

Other materials and schedules available

HARDWARE:

Stud Bolts:A193 Gr. B7 Steel

Hex Nuts:A194 Gr. 2H Steel

Jackscrew:C1018 Hardened Square Head Screws

Pipe Plugs:Hex Head, Forged Steel

Ring Gaskets:C4430 Non-Asbestos

Manufactured to meet

A.G.A Report #3-2

A.P.I 14.3

ASME SPECIFICATIONS

Orifice Plates sold seperate

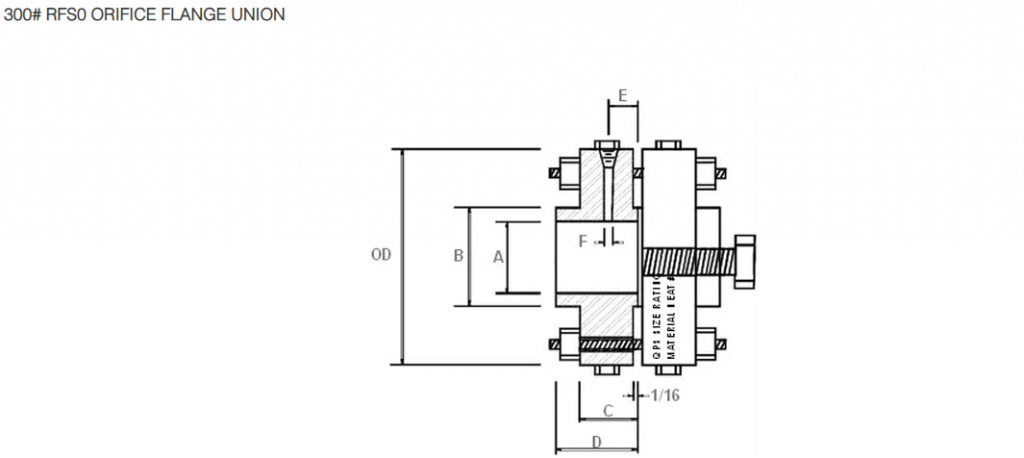

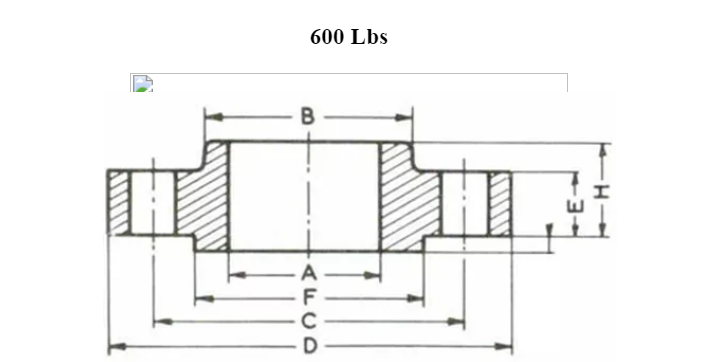

600# RFS0 ORIFICE FLANGE UNION

MATERIALS:

Domestic A105 (C.S.) AND A182 (S.S.)

Other materials and schedules available

HARDWARE:

Stud Bolts:A193 Gr. B7 Steel

Hex Nuts:A194 Gr. 2H Steel

Jackscrew:C1018 Hardened Square Head Screws

Pipe Plugs:Hex Head, Forged Steel

Ring Gaskets: C4430 Non-Asbestos

Manufactured to meet

A.G.A Report #3

A.P.I 14.3

ASME SPECIFICATIONS

Orifice Plates sold seperate

Uses of orifice flanges:

Orifice flange is used to flow/rate metering of piping systems.

They are used for all intensive purposes, similar to weld neck and slip-on flanges with extra machining.

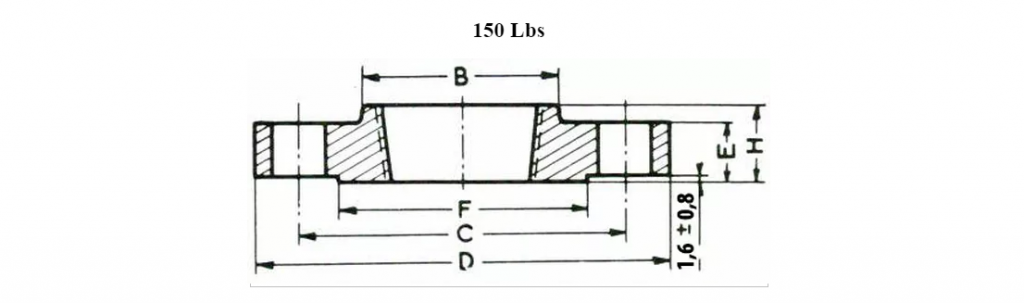

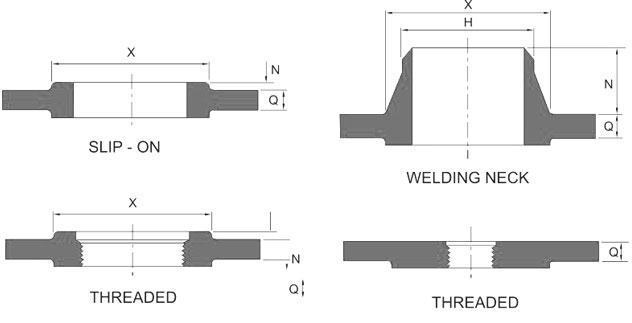

SLIP ON FLANGES

A Slip-On Flange is bored sightly larger than the outer Diameter of the matching pipe. The pipe slip into the flange prior to welding both inside and outside to prevent leaks.The British standard flanges manufactured by us pertain to all Standards like BS10 1962 Table D,E,F,H IS 6392 Table 5,17,26 IS 1538 in slip. These are manufactured using mild steel both in slip-on and blind type. Our quality slip on flanges are ideal for lower pressure applications. Their ease of fitting and welding reduces fabrication costs. Our professional engineering team is involved in innovating durable and high-quality products to cater to our clients’ needs.

The flange is slipped over the pipe and then welded both inside and outside to provide sufficient Strength and prevent leakage. This flange is used in preference to weld necks by many users because of its lower cost and the fact that less accuracy is required when cutting pipe to length.

Sizes for Slip On Flanges

All Slip On Flanges are available available in sizes from 1/4” through to any size.

Wall Thickness for Slip On Flanges

Schedule 5s through to Schedule XXS and heavier.

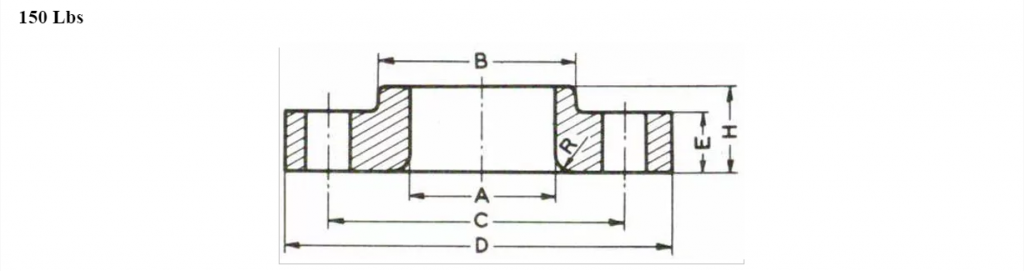

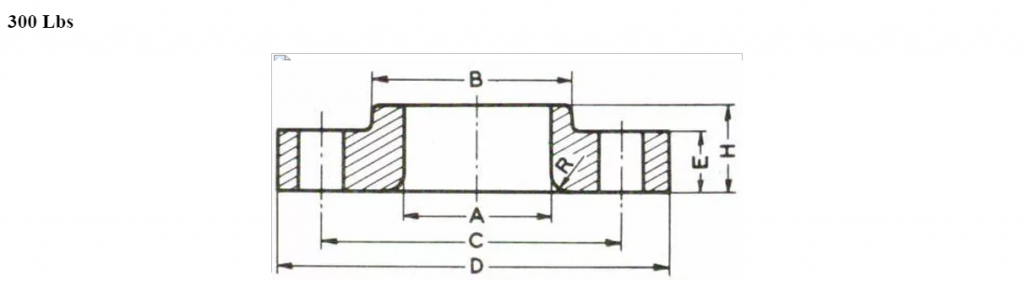

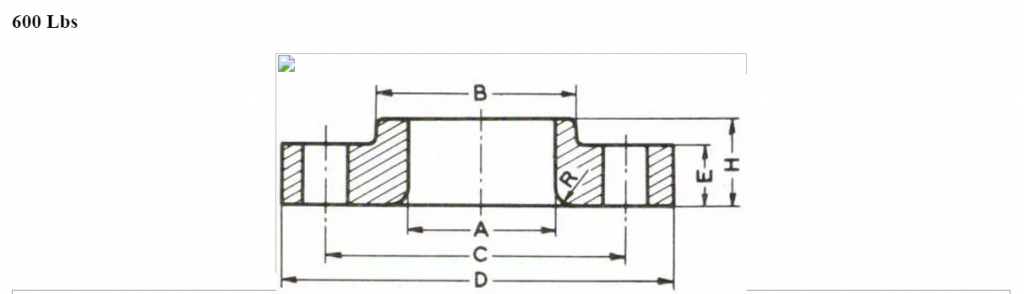

Dimensions

Diameter : 1/2″ à 24″

Pressure class : 150# – 300# – 600# – 1500#

Dimensions and Pressure Ratings for Slip On Flanges:

– ANSI, MSS- SP-44, BS3293, API 605 150lb through to 2500lb

– Flange Facings: Raised Face, Ring Type Joint, Large Tongue & Groove, Small Tongue & Groove

– BS4504 – PN6, 10, 16, 25, 64

– BS10 – Table D, E, F, & H

– DIN Standards

Variations

Face finish : Raised face (RF) – Flat face (FF) – RTJ

Variations : Reducing Slip On – Orifice Slip On

Standards

ASTM A182 – ASME SA182 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’

ASME B16.5– ‘Pipe Flanges and Flanged Fittings’

ASME B16.36 -‘Orifice Flanges’

ASME B16.47 – ‘Large Diameter Steel Flanges NPS26 Through NPS60’

MSS SP-6 – ‘Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings’

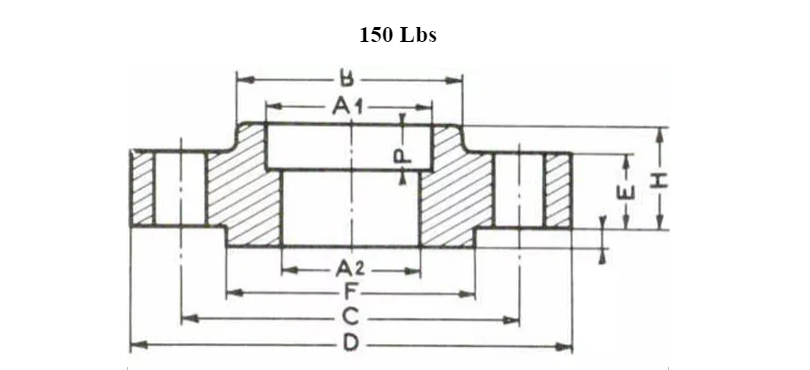

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 90 | 9.6 | 35.05 | 30 | 22.2 | 14 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 11.2 | 42.93 | 38 | 27.7 | 14 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 12.7 | 50.80 | 49 | 34.5 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 14.3 | 63.50 | 59 | 43.2 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 15.9 | 73.15 | 65 | 49.5 | 21 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 17.5 | 91.95 | 78 | 61.9 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 20.7 | 104.65 | 90 | 74.6 | 27 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 22.3 | 127.00 | 108 | 90.7 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2″ | 215 | 22.3 | 139.70 | 122 | 103.4 | 30 | 8 | 19.05 | 177.8 |

| 4″ | 230 | 22.3 | 157.22 | 135 | 116.1 | 32 | 8 | 19.05 | 190.5 |

| 5″ | 255 | 22.3 | 185.67 | 164 | 143.8 | 35 | 8 | 22.22 | 215.9 |

| 6″ | 280 | 23.9 | 215.90 | 192 | 170.7 | 38 | 8 | 22.22 | 241.3 |

| 8″ | 345 | 27.0 | 269.75 | 246 | 221.5 | 43 | 8 | 22.22 | 298.5 |

| 10″ | 405 | 28.6 | 323.85 | 305 | 276.2 | 48 | 12 | 25.40 | 362.0 |

| 12″ | 485 | 30.2 | 381.00 | 365 | 327.0 | 54 | 12 | 25.40 | 431.8 |

| 14″ | 535 | 33.4 | 412.75 | 400 | 359.2 | 56 | 12 | 28.57 | 476.3 |

| 16″ | 595 | 35.0 | 469.90 | 457 | 410.5 | 62 | 16 | 28.57 | 539.8 |

| 18″ | 635 | 38.1 | 533.40 | 505 | 461.8 | 67 | 16 | 31.75 | 577.9 |

| 20″ | 700 | 41.3 | 584.20 | 559 | 513.1 | 71 | 20 | 31.75 | 635.0 |

| 24″ | 815 | 46.1 | 692.15 | 663 | 616.0 | 81 | 20 | 34.92 | 749.3 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

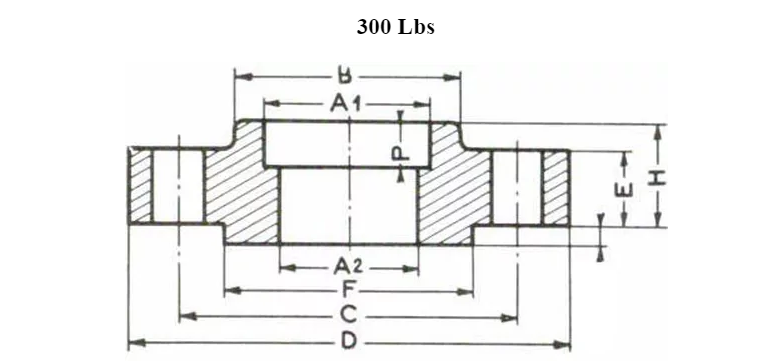

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 21.3 | 12.7 | 35.05 | 38 | 22.2 | 21 | 4 | 15.87 | 66.7 |

| 3/4″ | 26.7 | 14.3 | 42.93 | 48 | 27.7 | 24 | 4 | 19.05 | 82.6 |

| 1″ | 33.4 | 15.9 | 50.80 | 54 | 34.5 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 42.2 | 17.5 | 63.50 | 64 | 43.2 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 48.3 | 19.1 | 73.15 | 70 | 49.5 | 29 | 4 | 22.22 | 114.3 |

| 2″ | 60.3 | 20.7 | 91.95 | 84 | 61.9 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 73.0 | 23.9 | 104.65 | 100 | 74.6 | 37 | 8 | 22.22 | 149.2 |

| 3″ | 88.9 | 27.0 | 127.00 | 117 | 90.7 | 41 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 101.6 | 28.6 | 139.70 | 133 | 103.4 | 43 | 8 | 22.22 | 184.2 |

| 4″ | 114.3 | 30.2 | 157.22 | 146 | 116.1 | 46 | 8 | 22.22 | 200.0 |

| 5″ | 141.3 | 33.4 | 185.67 | 178 | 143.8 | 49 | 8 | 22.22 | 235.0 |

| 6″ | 168.3 | 35.0 | 215.90 | 206 | 170.7 | 51 | 12 | 22.22 | 269.9 |

| 8″ | 219.1 | 39.7 | 269.75 | 260 | 221.5 | 60 | 12 | 25.40 | 330.2 |

| 10″ | 273.0 | 46.1 | 323.85 | 321 | 276.2 | 65 | 16 | 28.57 | 387.4 |

| 12″ | 323.8 | 49.3 | 381.00 | 375 | 327.0 | 71 | 16 | 31.75 | 450.8 |

| 14″ | 355.6 | 52.4 | 412.75 | 425 | 359.2 | 75 | 20 | 31.75 | 514.4 |

| 16″ | 406.4 | 55.6 | 469.90 | 483 | 410.5 | 81 | 20 | 34.92 | 571.5 |

| 18″ | 457.0 | 58.8 | 533.40 | 533 | 461.8 | 87 | 24 | 34.92 | 628.6 |

| 20″ | 508.0 | 62.0 | 584.2td> | 587 | 513.1 | 94 | 24 | 34.92 | 685.8 |

| 24″ | 610.0 | 68.3 | 692.15 | 702 | 616.0 | 105 | 24 | 41.27 | 812.8 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

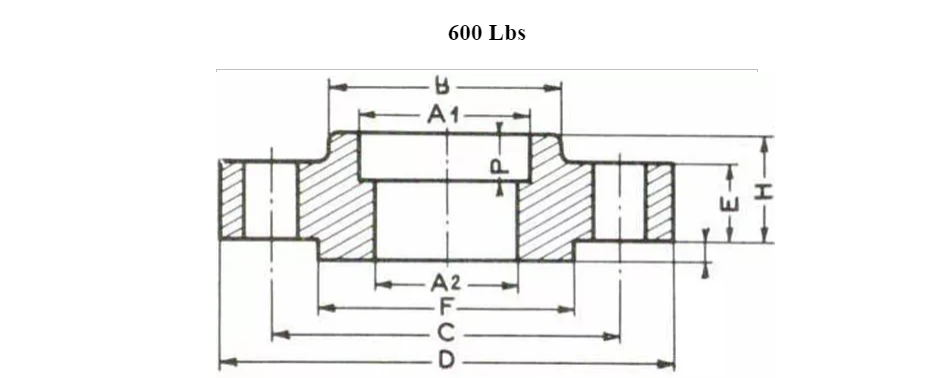

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 21.3 | 14.3 | 35.05 | 38 | 22.2 | 22 | 4 | 15.87 | 66.7 |

| 3/4″ | 26.7 | 15.9 | 42.93 | 48 | 27.7 | 25 | 4 | 19.05 | 82.6 |

| 1″ | 33.4 | 17.5 | 50.80 | 54 | 34.5 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 42.2 | 20.7 | 63.50 | 64 | 43.2 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 48.3 | 22.3 | 73.15 | 70 | 49.5 | 32 | 4 | 22.22 | 114.3 |

| 2″ | 60.3 | 25.4 | 91.95 | 84 | 61.9 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 73.0 | 28.6 | 104.65 | 100 | 74.6 | 41 | 8 | 22.22 | 149.2 |

| 3″ | 88.9 | 31.8 | 127.00 | 117 | 90.7 | 46 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 101.6 | 35.0 | 139.70 | 133 | 103.4 | 49 | 8 | 25.40 | 184.2 |

| 4″ | 114.3 | 38.1 | 157.22 | 152 | 116.1 | 54 | 8 | 25.40 | 215.9 |

| 5″ | 141.3 | 44.5 | 185.67 | 189 | 143.8 | 60 | 8 | 28.57 | 266.7 |

| 6″ | 168.3 | 47.7 | 215.90 | 222 | 170.7 | 67 | 12 | 28.57 | 292.1 |

| 8″ | 219.1 | 55.6 | 269.75 | 273 | 221.5 | 76 | 12 | 31.75 | 349.2 |

| 10″ | 273.0 | 63.5 | 325.85 | 343 | 276.2 | 86 | 16 | 34.92 | 431.8 |

| 12″ | 323.8 | 66.7 | 381.00 | 400 | 327.0 | 92 | 20 | 34.92 | 489.0 |

| 14″ | 355.6 | 69.9 | 412.75 | 432 | 359.2 | 94 | 20 | 38.10 | 527.0 |

| 16″ | 406.4 | 76.2 | 469.90 | 495 | 410.5 | 106 | 20 | 41.27 | 603.2 |

| 18″ | 457.0 | 82.6 | 533.40 | 546 | 461.8 | 117 | 20 | 44.45 | 654.0 |

| 20″ | 508.0 | 88.9 | 584.20 | 610 | 513.1 | 127 | 24 | 44.45 | 723.9 |

| 24″ | 610.0 | 101.6 | 692.15 | 718 | 616.0 | 140 | 24 | 50.80 | 838.2 |

6,4 raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

SOCKET WELD FLANGES

Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow. When provided with an internal weld, the static strength of this flange is equal to slip-on flange, but the fatigue strength is 50% greater than double welding slip-on flanges. Smooth bore conditions in such a flange can easily be attained without having to bevel the flange face and, after welding, to re-face the socket weld flange as would be required with slip-on flanges. For this reason, the internally welded flange is popular in chemical process piping. The counter bore is sightly larger than the Outer Diameter of the matching pipe, allowing the pipe to be inserted. A restriction is built into the bottom of the bore, which acts as a shoulder for the pipe to rest on, and has the same I.D. of matching pipe. The flow is not restricted in any direction.

Dimensions

Diameter : 1/2″ à 24″

pressure class : 150# – 300# – 600# – 1500#

Schedules : SCH10S – SCH40S – SCH80S – SCH160

Variations

Face finish : Raised face (RF) – Flat face (FF) – RTJ –

Variations : Reducing Socket Weld

Standards

ASTM A182 – ASME SA182 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’

ASME B16.5 – ‘Pipe Flanges and Flanged Fittings’

MSS SP-6 – ‘Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings’

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 90 | 11.2 | 35.05 | 30 | 22.2 | 14 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 12.7 | 42.92 | 38 | 27.7 | 14 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 14.3 | 50.80 | 49 | 34.5 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 15.9 | 63.50 | 59 | 43.2 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 17.5 | 73.15 | 65 | 49.5 | 21 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 19.1 | 91.94 | 78 | 61.9 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 22.3 | 104.65 | 90 | 74.6 | 27 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 23.9 | 127.00 | 108 | 90.7 | 29 | 4 | 19.05 | 152.4 |

1,6mm raised face not included in the E & H dimensions

See below for the A2 dimension

The dimensions are in millimeters

Source : ASME B16.5 – 2007

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 95 | 12.7 | 35.05 | 38 | 22.2 | 21 | 4 | 15.87 | 66.7 |

| 3/4″ | 115 | 14.3 | 42.92 | 48 | 27.7 | 24 | 4 | 19.05 | 82.6 |

| 1″ | 125 | 15.9 | 50.80 | 54 | 34.5 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 135 | 17.5 | 63.50 | 64 | 43.2 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 155 | 19.1 | 73.15 | 70 | 49.5 | 29 | 4 | 22.22 | 114.3 |

| 2″ | 165 | 20.7 | 91.94 | 84 | 61.9 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 190 | 23.9 | 104.65 | 100 | 74.6 | 37 | 8 | 22.22 | 149.2 |

| 3″ | 210 | 27.0 | 127.00 | 117 | 90.7 | 41 | 8 | 22.22 | 168.3 |

1,6mm raised face not included in the E & H dimensions

See below for the A2 dimension

The dimensions are in millimeters

Source : ASME B16.5 – 2007

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | >Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 95 | 14.3 | 35.05 | 38 | 22.2 | 22 | 4 | 15.87 | 66.7 |

| 3/4″ | 115 | 15.9 | 42.92 | 48 | 27.7 | 25 | 4 | 19.05 | 82.6 |

| 1″ | 125 | 17.5 | 50.80 | 54 | 34.5 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 135 | 20.7 | 63.50 | 64 | 43.2 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 155 | 22.3 | 73.15 | 70 | 49.5 | 32 | 4 | 22.22 | 114.3 |

| 2″ | 165 | 25.4 | 91.94 | 84 | 61.9 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 190 | 28.6 | 104.65 | 100 | 74.6 | 41 | 8 | 22.22 | 149.2 |

| 3″ | 210 | 31.8 | 127.00 | 117 | 90.7 | 46 | 8 | 22.22 | 168.3 |

6,4mm raised face not included in the E & H dimensions

See below for the A2 dimension

The dimensions are in millimeters

Source : ASME B16.5 – 2007

InNER diameter depending on thicknesses - A2

| Nominal Bore | SCH10S | SCH40S | SCH80S | SCH160 |

|---|---|---|---|---|

| 1/2″ | 17.1 | 15.8 | 13.9 | 11.8 |

| 3/4″ | 22.4 | 20.9 | 18.8 | 15.6 |

| 1″ | 27.8 | 26.6 | 24.3 | 20.7 |

| 1 1/4″ | 36.6 | 35.1 | 32.5 | 29.5 |

| 1 1/2″ | 42.7 | 40.9 | 38.1 | 34 |

| 2″ | 54.7 | 52.5 | 49.2 | 42.9 |

| 2 1/2″ | 66.9 | 62.7 | 59 | 54 |

| 3″ | 82.8 | 77.9 | 73.7 | 66.7 |

The dimensions are in millimeters

Source : ASME B16.5 – 2007

FLATE FLANGES

Our company is one of the leading companies that offer a wide range of Flat Flange to meet the needs of our clients. These flanges are fixed internally as well as externally according to the needs of our clients. Made up of high quality pure iron metal these flanges are anti-corrosive and highly durable in nature. Flat Flanges can be assembled as well as disassembled as per the convenience.

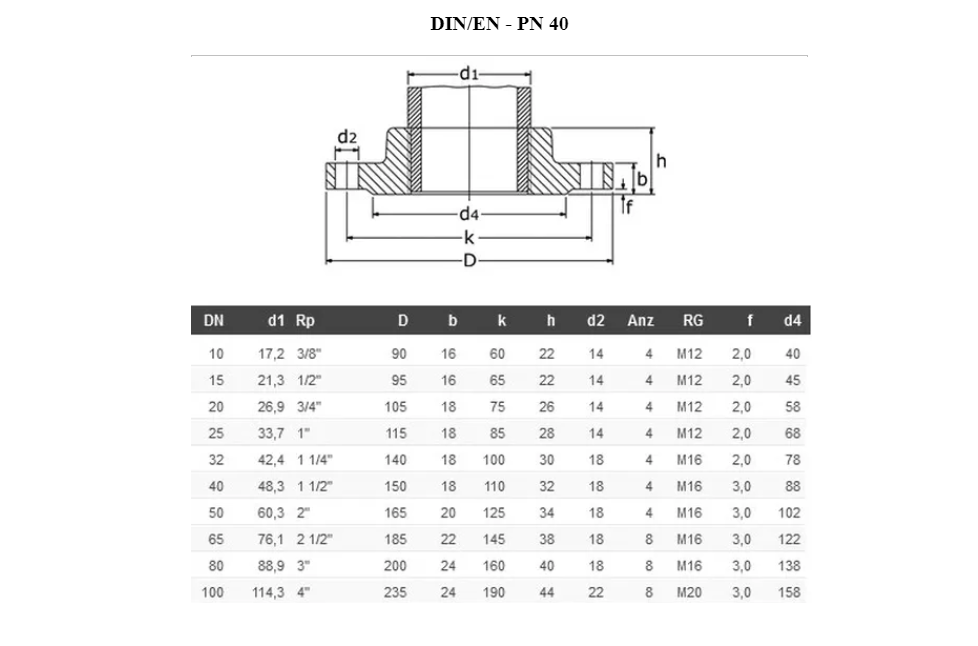

DIN2503 PN40 Flat Flange For Welding

DIN2503 PN40 Flat Flange For Welding Manufacturer Sanjay Bonny Forge Pvt.Ltd supplies DIN2503 PN40 Flat Flange For Welding, DIN WN forged Flange, DIN Blind flange, DIN threaded Flanges in forged steel, Stainless Steel, Carbon steel: C22.8, RST37.2, S235JR, P235GH, P245GH, P250GH, ASTM A105, ASTM A182 F304 (1.4306), F304L(1.4307), F316(1.4404), F316L(1.4404), F321(1.4541) etc..

carbon steel flat face flange

carbon steel flat face flange

Standard of Flange: ANSI,DIN,GOST,etc

Type of Flange: WN, SO, BL

Process of Flange: Forged,WELD FLANGE

Certification:API,ISO9001,CE

| FLANGES | |

| Production Type | Slip-on welding flange; welding neck flange; socket welding flange, threaded flange, lap joint flange; blind flange etc. |

| Size Range | From 1/2″ up to 60″ |

| Schedule | SCH STD, XS, XXS, SCH 10 ~ SCH 160 |

| Material Code: | |

| 1.Carbon steel | ASTM A105, ASTM A350 LF1/ LF2/LF3, ASTM |

| ASTM A694 F42/F46/F52/F56/F60/F65/F70 | |

| 2.Alloy steel | ASTM A182 F1, F5, F7, F9, F11, F12, F22, F91 |

| 3.Stainless steel | ASTM A182 F304/304L, F316/316L, F321, F347, |

| Standards | ANSI, ISO, JIS, DIN, BS,GB, SH, HG,QOST,ETC. |

| Certification | ISO9001:2000 , API, CE |

| Applications range | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, water etc. |

| Packaging: | Wooden Cases or pallet or as per customers requirement |

| Delivery Time: | At the earliest ,within the period required by customer. |

Dimensions

Dimension and weight of DIN2503 PN40 Flat Flange

| Nominal Pipe Size | Diameter of Pipe | Flange I.D | No. of holes | Flange Dia | Thk of Flange | Dia of Bolt Circle | Dia of Bolt Holes | Approx.Weight | |

| DN | ISO | DIN | D5 | BN | D | b | K | d2 | KG/PCS |

| 10 | – | 14 | 14.5 | 4 | 90 | 16 | 60 | 14 | 0.7 |

| 17.2 | – | 17.7 | 4 | 90 | 16 | 60 | 14 | 0.69 | |

| 15 | – | 20 | 21 | 4 | 95 | 16 | 65 | 14 | 0.77 |

| 21.3 | – | 22 | 4 | 95 | 16 | 65 | 14 | 0.77 | |

| 20 | – | 25 | 26 | 4 | 105 | 18 | 75 | 14 | 1.06 |

| 26.9 | – | 27.6 | 4 | 105 | 18 | 75 | 14 | 1.05 | |

| 25 | – | 30 | 31 | 4 | 115 | 18 | 85 | 14 | 1.27 |

| 33.7 | – | 34.4 | 4 | 115 | 18 | 85 | 14 | 1.25 | |

| 32 | – | 38 | 39 | 4 | 140 | 18 | 100 | 18 | 1.86 |

| 42.4 | – | 43.1 | 4 | 140 | 18 | 100 | 18 | 1.83 | |

| 40 | – | 44.5 | 45.5 | 4 | 150 | 18 | 110 | 18 | 2.12 |

| 48.3 | – | 49 | 4 | 150 | 18 | 110 | 18 | 2.09 | |

| 50 | – | 57 | 58.1 | 4 | 165 | 20 | 125 | 18 | 2.78 |

| 60.3 | – | 61.1 | 4 | 165 | 20 | 125 | 18 | 2.74 | |

| 65 | 76.1 | – | 77.1 | 8 | 185 | 22 | 145 | 18 | 3.48 |

| 80 | 88.9 | – | 90.3 | 8 | 200 | 24 | 160 | 18 | 4.33 |

| 100 | – | 108 | 109.6 | 8 | 235 | 24 | 190 | 22 | 5.82 |

| 114.3 | – | 115.9 | 8 | 235 | 24 | 190 | 22 | 5.61 | |

| 125 | – | 133 | 134.8 | 8 | 270 | 26 | 220 | 26 | 7.91 |

| 139.7 | – | 141.6 | 8 | 270 | 26 | 220 | 26 | 7.6 | |

| 150 | – | 159 | 161.1 | 8 | 300 | 28 | 250 | 26 | 10.12 |

| 168.3 | – | 170.5 | 8 | 300 | 28 | 250 | 26 | 9.58 | |

| 175 | 193.7 | – | 196.1 | 12 | 350 | 32 | 295 | 30 | 14.45 |

| 200 | 219.1 | – | 221.8 | 12 | 375 | 34 | 320 | 30 | 16.9 |

| 250 | – | 267 | 270.2 | 12 | 450 | 38 | 385 | 33 | 27.28 |

| 273 | – | 276.2 | 12 | 450 | 38 | 385 | 33 | 26.51 | |

| 300 | 323.9 | – | 327.6 | 16 | 515 | 42 | 450 | 33 | 36.38 |

| 350 | 355.6 | – | 359.7 | 16 | 580 | 46 | 510 | 36 | 52.83 |

| – | 368 | 372.2 | 16 | 580 | 46 | 510 | 36 | 50.24 | |

| 400 | 406.4 | – | 411 | 16 | 660 | 50 | 585 | 39 | 74.71 |

| – | 419 | 423.7 | 16 | 660 | 50 | 585 | 39 | 71.44 | |

| 500 | 508 | – | 513.6 | 20 | 755 | 52 | 670 | 42 | 86.87 |

| 600 | 610 | – | 616.5 | 20 | 890 | 54 | 795 | 48 | 121.84 |

| 700 | 711 | – | 716 | 24 | 995 | 58 | 900 | 48 | 150.93 |

| 800 | 813 | – | 818 | 24 | 1140 | 64 | 1030 | 56 | 219.08 |

| 900 | 914 | – | 920 | 28 | 1250 | 70 | 1140 | 56 | 271.16 |

| 1000 | 1016 | – | 1022 | 28 | 1360 | 78 | 1250 | 56 | 344.95 |

LAP JOINT FLANGES

Lap Joint flanges are used on piping fitted with with lapped pipe or with lap joint stub ends. The lap joint flange with the stub end assembly are normally used in systems requiring frequent dismantling for inspection and cleaning and where the ability to swivel flanges and to align bolt holes materially eases the erection of large diameter or unusually stiff piping. These flanges are also used in applications where there is a need to facilitate bolt alignment. These type of flanges are similar to slip-on flanges. The only difference is that it has a curved radius at the bore and face to accommodate a lap joint stub end. They may be used at all pressures and are available in a full size range. These lap joint flanges slip over the pipe, and are not welded. They are otherwise fastened to it. Here the bolting pressure is transferred to the gasket by the pressure of the flange against the back of the pipe lap.

Dimensions

Diameter : 1/2″ à 24″

Pressure class : 150# – 300# – 600# – 1500#

Standards

ASTM A182 – ASME SA182 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’

ASME B16.5- ‘Pipe Flanges and Flanged Fittings’

MSS SP-6 – ‘Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings’

The tables below show the most common sizes but are not exhaustive.

| Drilling | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (B) | Dia. (A) | Height (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 90 | 11.2 | 30 | 22.9 | 16 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 12.7 | 38 | 28.2 | 16 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 14.3 | 49 | 34.9 | 17 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 15.9 | 59 | 43.7 | 21 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 17.5 | 65 | 50.0 | 22 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 20.7 | 78 | 62.5 | 25 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 22.3 | 90 | 75.4 | 29 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 23.9 | 108 | 91.4 | 30 | 4 | 19.05 | 152.4 |

| 3 1/2″ | 215 | 23.9 | 122 | 104.1 | 32 | 8 | 19.05 | 177.8 |

| 4″ | 230 | 23.9 | 135 | 116.8 | 33 | 8 | 19.05 | 190.5 |

| 5″ | 255 | 23.9 | 164 | 144.4 | 36 | 8 | 22.22 | 215.9 |

| 6″ | 280 | 25.4 | 192 | 171.4 | 40 | 8 | 22.22 | 241.3 |

| 8″ | 345 | 28.6 | 246 | 222.2 | 44 | 8 | 22.22 | 298.5 |

| 10″ | 405 | 30.2 | 305 | 277.4 | 49 | 12 | 25.40 | 362.0 |

| 12″ | 485 | 31.8 | 365 | 328.2 | 56 | 12 | 25.40 | 431.8 |

| 14″ | 535 | 35.0 | 400 | 360.2 | 79 | 12 | 28.57 | 476.3 |

| 16″ | 595 | 36.6 | 457 | 411.2 | 87 | 16 | 28.57 | 539.8 |

| 18″ | 635 | 39.7 | 505 | 462.3 | 97 | 16 | 31.75 | 577.9 |

| 20″ | 700 | 42.9 | 559 | 514.4 | 103 | 20 | 31.75 | 635.0 |

| 24″ | 815 | 47.7 | 663 | 616.0 | 111 | 20 | 34.92 | 749.3 |

The dimensions are in millimeters

Source : ASME B16.5 – 2007

| Drilling | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (B) | Dia. (A) | Height (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 95 | 14.3 | 38 | 22.9 | 22 | 4 | 15.87 | 66.7 |

| 3/4″ | 115 | 15.9 | 48 | 28.2 | 25 | 4 | 19.05 | 82.6 |

| 1″ | 125 | 17.5 | 54 | 34.9 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 135 | 19.1 | 64 | 43.7 | 27 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 155 | 20.7 | 70 | 50.0 | 30 | 4 | 22.22 | 114.3 |

| 2″ | 165 | 22.3 | 84 | 62.5 | 33 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 190 | 25.4 | 100 | 75.4 | 38 | 8 | 22.22 | 149.2 |

| 3″ | 210 | 28.6 | 117 | 91.4 | 43 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 230 | 30.2 | 133 | 104.1 | 44 | 8 | 22.22 | 184.2 |

| 4″ | 255 | 31.8 | 146 | 116.8 | 48 | 8 | 22.22 | 200.0 |

| 5″ | 280 | 35.0 | 178 | 144.4 | 51 | 8 | 22.22 | 235.0 |

| 6″ | 320 | 36.6 | 206 | 171.4 | 52 | 12 | 22.22 | 269.9 |

| 8″ | 380 | 41.3 | 260 | 222.2 | 62 | 12 | 25.40 | 330.2 |

| 10″ | 445 | 47.7 | 321 | 277.4 | 95 | 16 | 28.57 | 387.4 |

| 12″ | 520 | 50.8 | 375 | 328.2 | 102 | 16 | 31.75 | 450.8 |

| 14″ | 585 | 54.0 | 425 | 360.2 | 111 | 20 | 31.75 | 514.4 |

| 16″ | 650 | 57.2 | 483 | 411.2 | 121 | 20 | 34.29 | 571.5 |

| 18″ | 710 | 60.4 | 533 | 462.3 | 130 | 24 | 34.29 | 628.6 |

| 20″ | 775 | 63.5 | 587 | 514.4 | 140 | 24 | 34.29 | 685.8 |

| 24″ | 915 | 69.9 | 702 | 616.0 | 152 | 24 | 41.27 | 812.8 |

The dimensions are in millimeters

Source : ASME B16.5 – 2007

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (B) | Dia. (A) | Height (H) | Nbr | Holes | Dia. (C) |

|---|---|---|---|---|---|---|---|---|

| 1/2″ | 95 | 14.3 | 38 | 23.6 | 22 | 4 | 15.87 | 66.7 |

| 3/4″ | 115 | 15.9 | 48 | 29.0 | 25 | 4 | 19.05 | 82.6 |

| 1″ | 125 | 17.5 | 54 | 35.8 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 135 | 20.7 | 64 | 44.4 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 155 | 22.3 | 70 | 50.6 | 32 | 4 | 22.22 | 114.3 |

| 2″ | 165 | 25.4 | 84 | 63.5 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 190 | 28.6 | 100 | 76.2 | 41 | 8 | 22.22 | 149.2 |

| 3″ | 210 | 31.8 | 117 | 92.2 | 46 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 230 | 35.0 | 133 | 104.9 | 49 | 8 | 25.40 | 184.2 |

| 4″ | 275 | 38.1 | 152 | 117.6 | 54 | 8 | 25.40 | 215.9 |

| 5″ | 330 | 44.5 | 189 | 144.4 | 60 | 8 | 28.57 | 266.7 |

| 6″ | 355 | 47.7 | 222 | 171.4 | 67 | 12 | 28.57 | 292.1 |

| 8″ | 420 | 55.6 | 273 | 222.2 | 76 | 12 | 31.75 | 349.2 |

| 10″ | 510 | 63.5 | 343 | 276.2 | 111 | 16 | 34.92 | 431.8 |

| 12″ | 560 | 66.7 | 400 | 328.6 | 117 | 20 | 34.92 | 489.0 |

| 14″ | 605 | 69.9 | 432 | 360.4 | 127 | 20 | 38.10 | 527.0 |

| 16″ | 685 | 76.2 | 495 | 411.2 | 140 | 20 | 41.27 | 603.2 |

| 18″ | 745 | 82.6 | 546 | 462.0 | 152 | 20 | 44.45 | 6654.0 |

| 20″ | 815 | 88.9 | 610 | 512.8 | 165 | 24 | 44.45 | 723.9 |

| 24″ | 940 | 101.6 | 718 | 614.4 | 184 | 24 | 50.80 | 838.2 |

The dimensions are in millimeters

Source : ASME B16.5 – 2007

THREADED FLANGS

Threaded Flanges are confined to special applications. Their chief merit lies in the fact that they can be assembled without welding this explains their use in extremely high pressure services, particularly at or near atmospheric temperature, when alloy steel is essential for strength and where the necessary post weld heat treatment is impractical. Threaded Flanges are unsuited for conditions involving temperature or bending stresses of any magnitude, particularly under cyclic conditions, where leakage through the threads may occur in relatively few cycles of heating or stress; sea welding is sometimes employed to overcome this, but cannot be considered as entirely satisfaction.

Dimensions

Diameter : 1/2″ à 24″

Pressure class : 150# – 300# – 600# – 1500#

Variations

Face finish : Raised face (RF) – Flat face (FF) – RTJ

Variations : Reducing Threaded

Standards

ASTM A182 – ASME SA182 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’

ASME B16.5 – ‘Pipe Flanges and Flanged Fittings’

MSS SP-6 – ‘Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings’ and Fittings’

| Drilling | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 90 | 9.6 | 35.05 | 30 | 14 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 11.2 | 42.92 | 38 | 14 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 12.7 | 50.80 | 49 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 14.3 | 63.50 | 59 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 15.9 | 73.15 | 65 | 21 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 17.5 | 91.94 | 78 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 20.7 | 104.65 | 90 | 27 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 22.3 | 127.00 | 108 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2″ | 215 | 22.3 | 139.70 | 122 | 30 | 8 | 19.05 | 177.8 |

| 4″ | 230 | 22.3 | 157.22 | 135 | 32 | 8 | 19.05 | 190.5 |

| 5″ | 255 | 22.3 | 185.67 | 164 | 35 | 8 | 22.22 | 215.9 |

| 6″ | 280 | 23.9 | 215.90 | 192 | 38 | 8 | 22.22 | 241.3 |

| 8″ | 345 | 27.0 | 269.75 | 246 | 43 | 8 | 22.22 | 298.5 |

| 10″ | 405 | 28.6 | 323.85 | 305 | 48 | 12 | 25.40 | 362.0 |

| 12″ | 485 | 30.2 | 381.00 | 365 | 54 | 12 | 25.40 | 431.8 |

| 14″ | 535 | 33.4 | 412.75 | 400 | 56 | 12 | 28.57 | 476.3 |

| 16″ | 595 | 35.0 | 469.90 | 457 | 62 | 16 | 28.57 | 539.8 |

| 18″ | 635 | 38.1 | 533.40 | 505 | 67 | 16 | 31.75 | 577.9 |

| 20″ | 700 | 41.3 | 584.20 | 559 | 71 | 20 | 31.75 | 635.0 |

| 24″ | 815 | 46.1 | 692.15 | 663 | 81 | 20 | 34.92 | 749.3 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 95 | 12.7 | 35.05 | 38 | 23.6 | 21 | 4 | 15.87 | 66.7 |

| 3/4″ | 115 | 14.3 | 42.92 | 48 | 29.0 | 24 | 4 | 19.05 | 82.6 |

| 1″ | 125 | 15.9 | 50.80 | 54 | 35.8 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 135 | 17.5 | 63.50 | 64 | 44.4 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 155 | 19.1 | 73.15 | 70 | 50.3 | 29 | 8 | 22.22 | 114.3 |

| 2″ | 165 | 20.7 | 91.94 | 84 | 63.5 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 190 | 23.9 | 104.65 | 100 | 76.2 | 37 | 8 | 22.22 | 149.2 |

| 3″ | 210 | 27.0 | 127.00 | 117 | 92.2 | 41 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 230 | 28.6 | 139.70 | 133 | 104.9 | 43 | 8 | 22.22 | 184.2 |

| 4″ | 255 | 30.2 | 157.22 | 146 | 117.6 | 46 | 8 | 22.22 | 200.0 |

| 5″ | 280 | 33.4 | 185.67 | 178 | 144.4 | 49 | 8 | 22.22 | 235.0 |

| 6″ | 320 | 35.0 | 215.90 | 206 | 171.4 | 51 | 12 | 22.22 | 269.9 |

| 8″ | 380 | 39.7 | 269.75 | 260 | 222.2 | 60 | 12 | 25.40 | 330.2 |

| 10″ | 445 | 46.1 | 323.85 | 321 | 276.2 | 65 | 16 | 28.57 | 387.4 |

| 12″ | 520 | 49.3 | 381.00 | 375 | 328.6 | 71 | 16 | 31.75 | 450.8 |

| 14″ | 585 | 52.4 | 412.75 | 425 | 360.4 | 75 | 20 | 31.75 | 514.4 |

| 16″ | 650 | 55.6 | 469.90 | 483 | 411.2 | 81 | 20 | 34.92 | 571.5 |

| 18″ | 710 | 58.8 | 533.40 | 533 | 462.0 | 87 | 24 | 34.92 | 628.6 |

| 20″ | 775 | 62.0 | 584.20 | 587 | 512.8 | 94 | 24 | 34.92 | 685.8 |

| 24″ | 915 | 68.3 | 692.15 | 702 | 614.4 | 105 | 24 | 41.27 | 812.8 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

REDUCING FLANGES

Our range of reducing flanges is made of premium quality stainless steel. The reducing flanges are widely used in various industrial applications. Available in various configuration, these reducing flanges are suitable to connect tubings and pipe sections.

These stainless steel reducing flanges offer various advantages such as close tolerances, reliability and durability. Moreover, the SS reducing flanges are supplied in customized specifications.

Types of Reducing Flanges :

Welding Neck

Slip-On

Threaded

Alloy Steel : ASTM A 182, GR F1, F11, F22, F5, F9, F91

Carbon Steel : ASTM A 105, ASTM A 181

Copper Alloys : Copper, Brass & Gunmetal

Nickel Alloys : Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Size : 1/8″ NB TO 48″NB.

Class : 150#, 300#,400 #,600#,900#, 1500# & 2500 #.

Standard

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10

WELD NECK FLANGES SERIES A OR B

Weld Neck Flanges are drilled(machined) with the wall thickness of the flange having the same dimensions of the matching pipe, the lighter the pipe is, the larger the bore, conversely, the heavier the pipe, the small the bore, they are normally used for highpressure, cold or hot temperature.

Stainless Steel:

ASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel:

ASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.

Nickel Alloy

ASTM / ASME SB 564 UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

ASTM / ASME SB 160 UNS 2201 (NICKEL 201 )

ASTM / ASME SB 472 UNS 8020 (ALLOY 20 / 20 CB 3)

Copper Alloy

ASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600.

ASTM / ASME SB 151 UNS NO. 70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200.

Carbon Steel

ASTM / ASME A 105

ASTM / ASME A 350 LF 2

Alloy Steel

ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91

Dimensions

Welding neck flange bores according ASME/ANSI B16.5-1996 Pipe Flanges and Flanged Fittings – can be found in the table below:

| Welding Neck Flange Bores | |||||||

| Nominal Pipe Size (inches) | Outside Diameter (inches) | Inside Diameter (inches) | |||||

| Light Wall 1) | Schedule 20 | Schedule 30 | Standard Wall | Schedule 40 | Schedule 60 | ||

| 1/2 | 0.840 | 0.674 | – | – | 0.622 | 0.622 | – |

| 3/4 | 1.050 | 0.884 | – | – | 0.824 | 0.824 | – |

| 1 | 1.315 | 1.097 | – | – | 1.049 | 1.049 | – |

| 1 1/4 | 1.660 | 1.442 | – | – | 1.380 | 1.380 | – |

| 1 1/2 | 1.900 | 1.682 | – | – | 1.610 | 1.610 | – |

| 2 | 2.375 | 2.157 | – | – | 2.067 | 2.067 | – |

| 2 1/2 | 2.875 | 2.635 | – | – | 2.469 | 2.469 | – |

| 3 | 3.500 | 3.260 | – | – | 3.068 | 3.068 | – |

| 3 1/2 | 4.000 | 3.760 | – | – | 3.548 | 3.548 | – |

| 4 | 4.500 | 4.260 | – | – | 4.026 | 4.026 | – |

| 5 | 5.563 | 5.295 | – | – | 5.047 | 5.047 | – |

| 6 | 6.625 | 6.357 | – | – | 6.065 | 6.065 | – |

| 8 | 8.625 | 8.329 | 8.125 | 8.071 | 7.981 | 7.981 | 7.813 |

| 10 | 10.750 | 10.420 | 10.250 | 10.136 | 10.020 | 10.020 | 9.750 |

| 12 | 12.750 | 12.390 | 12.250 | 12.090 | 12.000 | 11.938 | 11.626 |

| 14 | 14.000 | 13.500 | 13.376 | 13.250 | 13.250 | 13.124 | 12.812 |

| 16 | 16.000 | 15.500 | 15.376 | 15.250 | 15.250 | 15.000 | 14.688 |

| 18 | 18.000 | 17.500 | 17.376 | 17.124 | 17.250 | 16.876 | 16.500 |

| 20 | 20.000 | 19.500 | 19.250 | 19.000 | 19.250 | 18.812 | 18.376 |

| 24 | 24.000 | 23.500 | 23.250 | 22.876 | 23.250 | 22.624 | 22.062 |

| 30 | 30.000 | 29.376 | 29.000 | 28.750 | 29.250 | – | – |

| 36 | 36.000 | 35.376 | 35.000 | 34.750 | 35.250 | 34.500 | – |

| 42 | 42.000 | – | – | – | 41.250 | – | – |

| 48 | 48.000 | – | – | – | 47.250 | – | – |

| Welding Neck Flange Bores | ||||||||

| Nominal Pipe Size (inches) | Outside Diameter (inches) | Inside Diameter (inches) | ||||||

| Extra Strong | Schedule 80 | Schedule 100 | Schedule 120 | Schedule 140 | Schedule 160 | Double Extra Strong | ||

| 1/2 | 0.840 | 0.546 | 0.546 | – | – | – | 0.464 | 0.252 |

| 3/4 | 1.050 | 0.742 | 0.742 | – | – | – | 0.612 | 0.434 |

| 1 | 1.315 | 0.957 | 0.957 | – | – | – | 0.815 | 0.599 |

| 1 1/4 | 1.660 | 1.278 | 1.278 | – | – | – | 1.160 | 0.896 |

| 1 1/2 | 1.900 | 1.500 | 1.500 | – | – | – | 1.338 | 1.100 |

| 2 | 2.375 | 1.939 | 1.939 | – | – | – | 1.687 | 1.503 |

| 2 1/2 | 2.875 | 2.323 | 2.323 | – | – | – | 2.125 | 1.771 |

| 3 | 3.500 | 2.900 | 2.900 | – | – | – | 2.624 | 2.300 |

| 3 1/2 | 4.000 | 3.364 | 3.364 | – | – | – | – | 2.728 |

| 4 | 4.500 | 3.826 | 3.826 | – | 3.624 | – | 3.438 | 3.152 |

| 5 | 5.563 | 4.813 | 4.813 | – | 4.563 | – | 4.313 | 4.063 |

| 6 | 6.625 | 5.761 | 5.761 | – | 5.501 | – | 5.187 | 4.897 |

| 8 | 8.625 | 7.625 | 7.625 | 7.437 | 7.187 | 7.001 | 6.813 | 6.875 |

| 10 | 10.750 | 9.750 | 9.562 | 9.312 | 9.062 | 8.750 | 8.500 | 8.750 |

| 12 | 12.750 | 11.750 | 11.374 | 11.062 | 10.750 | 10.500 | 10.126 | 10.750 |

| 14 | 14.000 | 13.000 | 12.500 | 12.124 | 11.814 | 11.500 | 11.188 | – |

| 16 | 16.000 | 15.000 | 14.312 | 13.938 | 13.564 | 13.124 | 12.812 | – |

| 18 | 18.000 | 17.000 | 16.124 | 15.688 | 15.250 | 14.876 | 14.438 | – |

| 20 | 20.000 | 19.000 | 17.938 | 17.438 | 17.000 | 16.500 | 16.062 | – |

| 24 | 24.000 | 23.000 | 21.562 | 20.938 | 20.376 | 19.876 | 19.312 | – |

| 30 | 30.000 | 29.000 | – | – | – | – | – | – |

| 36 | 36.000 | 35.000 | – | – | – | – | – | – |

| 42 | 42.000 | 41.000 | – | – | – | – | – | – |

| 48 | 48.000 | 47.000 | – | – | – | – | – | – |

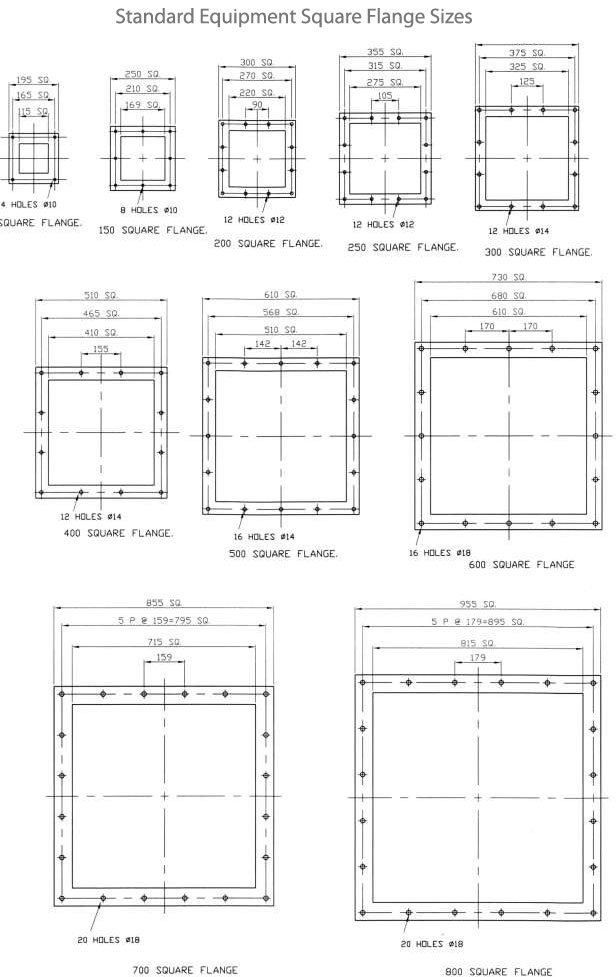

SQUARE FLANGES

Backed by our state-of-the-art manufacturing facility, we are capable of providing our clients with a comprehensive range of Square Flangesthat is available in various sizes and specifications. Our range is manufactured using high grade raw material, which is sourced from the reliable and certified vendors of the market to ensure quality. Moreover, our range can be customized as per the specifications detailed by the clients to fulfill their exact requirements in a better way.

Stainless Steel:

ASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel:

ASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.

Nickel Alloy

ASTM / ASME SB 564 UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

ASTM / ASME SB 160 UNS 2201 (NICKEL 201 )

ASTM / ASME SB 472 UNS 8020 (ALLOY 20 / 20 CB 3)

Copper Alloy

ASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600.

ASTM / ASME SB 151 UNS NO. 70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200.

Carbon Steel

ASTM / ASME A 105

ASTM / ASME A 350 LF 2

Alloy Steel

ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91.

Dimensions

Standard Equipment Square Flange Sizes:

150 Square Flange : 8 Holes Ø 10

200 Square Flange: 12 Holes Ø 12

250 Square Flange: 12 Holes Ø 12

300 Square Flange: 12 Holes Ø 14

400 Square Flange: 12 Holes Ø 14

500 Square Flange: 16 Holes Ø 14

600 Square Flange: 16 Holes Ø 18

700 Square Flange: 20 Holes Ø 18

800 Square Flange: 20 Holes Ø 18

Our range includes SHA+SHB (SHAB) Square Flanges and SSA+SSB (SSAB) Square Flanges.

Working Pressure for the Square Flanges available is 210 kg/cmª

Our range of sizes are from 1/4″NB – 6″NB.

Square flange Ø 40 mm pipe aperture

Solid twin hole flanges made of 304 AISI stainless steel. Extra strong and solid version to build compact and gas-tight connections. To take in the regarding pipe diameter, the central hole intake is constructed with a bore tolerance, which effects easy fitting, fixing and further processing. The flange plates can be mounted directly to elbow pipes, ordinary pipes or assemblies of any kind and form and allow you flexible construction.

Pipe aperture: 40 mm

Material thickness: 8 mm

Outside dimensions: 69×69 mm

Square Flanges Key Features:

Can be attached to the pipe without welding (sometimes an additional seal weld is used as well)

Ideal for higher pressure and temperature applications for small pipe sizes

Not recommended for larger loads, especially when subjected to higher torque

NOTE: This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required.

Standards: ANSI, AS2129, JIS, DIN, EN-1092-1, BS10, BS4504 etc

Nominal Pressure: PN0.25-PN42, 150LB-900LB, 5K–30K.

Nominal Diameter: DN10A-DN600A, NPS:3/8″-24″.

Square Flanges Materials: Carbon steel, stainless steel and alloy steel.

Printing: Carbon steel and alloy steel with yellow print, black print, oil or zinc.

Square Flanges Packing: Plywooden case.

Payment terms: both L/C at sight and T/T before shipment.

* We can also manufacture special application flanges and forgings that customers require.

Square Flanges Dimensions

Square Flanges ANSI B16.5

Square Flanges Class 150 lbs

Square Flanges Class 300 lbs

Square Flanges Class 400 lbs

Square Flanges Class 600 lbs

Square Flanges Class 900 lbs

Square Flanges Class 1500 lbs

Square Flanges Class 2500 lbs

GROOVE & TONGUE FLANGES

Flange Facings: Raised Face, Ring Type Joint, Large Tongue & Groove, Small Tongue & Groove

Flanges are available in the following material grades:

Stainless Steel

A182 F304/L

F310

F316/L

F321/H

F347/H

F410

F440

904L

Carbon Steel

A105, C22.8

Low Temperature Steel

A350 LF2, LF3, LF6

Alloy Steel

A182 F1, F5, F9, F11, F12, F22, F91

High Yield

A694 F42, F52, F60, F65, F70

6% Moly / Duplex & Super Duplex

A182 F44, F51, F53, F55

Nickel Alloys

200, 400, K500, 600, 625, 800, 825

Alloys

ALLOY 20

ALLOY C

ALLOY C276

ALLOY B2

Aluminium

5083, 5154, 5251, 6061, 6063, 6082

Unusual Grades

Bronze, Brass, Copper

Cupro Nickel

Titanium

Dimensions

Tongue and groove flanges per ANSI B16.21 (150-1500 lbs)

LONG WELD NECK FLANGES

Our extensive range of Long Weld Neck Flanges is used in general piping, refineries, and other related industries. These Long Weld Neck Flanges are procured from authentic vendors, who are selected on the basis of their market credibility. Our Long Weld Neck Flanges are appreciated for salient attributes such as corrosion resistance, high tolerance, and longer functional life.

Flanges are available in the following material grades:

Range

½” (15 NB) to 48” (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. Available with NACE MR 01-75

Stainless Steel

Grade : 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430L

Duplex Steel

Grade : 2205 (UNS No. S31803), 2507 (UNS No. S32750)

Nickel Alloy

Grade : Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Copper Alloy

Grade : UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

Standard

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10

OTHER : PLATE, PLATE BLANK

Value Added Services

HOT DIPPED GALVANIZING

HEAT TREATMENT

CNC MACHINING

THREADING

SCREWED FLANGES

We are one of the leading manufacturer of screwed flanges in India, we can supply stainless steel screwed flanges, carbon steel screwed flanges and nickel alloy screwed pipe flanges, the method includes forging and casting. Also, we can produce as per your drawings and specifications.

| Size | Weight (kg) | |

|---|---|---|

| Flange Table x Thread | ||

| “D” – 3″ | 3″ BSP | 2.7 |

| “D” – 4″ | 4″ BSP | 3.7 |

| “D” – 5″ | 5″ BSP | 4.7 |

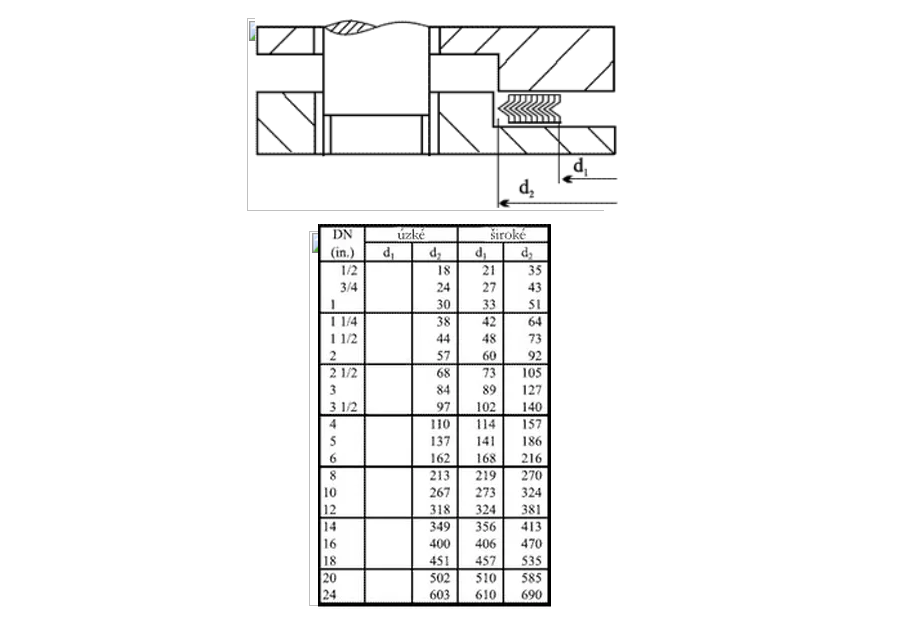

RING TYPE JOINT FLANGES

Our organization is involved in offering a wide range of Ring Joint Flanges, which is highly durable, resistance to heat, and has the ability to withstand any amount of stress. These Ring Type Joint Flanges are used in automobiles, and engineering related industries. We offer our range of Ring Joint Flanges in various dimensions and other technical specifications as per the specific requirements of our customers.

Range

½” (15 NB) to 48” (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. Available with NACE MR 01-75

Stainless Steel

Grade : 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430L

Duplex Steel

Grade : 2205 (UNS No. S31803), 2507 (UNS No. S32750)

Nickel Alloy

Grade : Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Copper Alloy

Grade : UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

Standard

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10

OTHER : PLATE, PLATE BLANK

Value Added Services

HOT DIPPED GALVANIZING

HEAT TREATMENT

CNC MACHINING

THREADING

FLANGE FACING TYPE & FINISH

We are involved in offering a quality range of Flanges, which is high in durability and can withstand extreme conditions. These flanges are available in different grades, class, and other technical specifications as per the client’s requirements. Our range is commonly used to connect other threaded components in low pressure and non-critical applications.

American Standard Series | ||

| STANDARD CODES | NOMINAL SIZE | PRESSURE GRADE |

| ANSI B 16.5(88) | 1/2″-24″ | Class 150、300、600、900、1500、2500 |

| ANSI B 16.47(90) | 26″-60″ | Class 150、300、600、900 |

| ASME B 16.5(96) | 1/2″-24″ | Class 150、300、600、900、1500、2500 |

| ISO7005-1(92) | 1/2″-24″ | PN2.0 5.0 11.0 15.0 26.0 42.0 |

| BS4504-3.1(89) | 1/2″-24″ | Class 150、300、600、900、1500、2500 |

| JPI 7S-15-93 | 1/2″-24″ | Class 150、300、600、900、1500、2500 |

| NF E29-203 | 1/2″-24″ | PN2.0 5.0 11.0 15.0 26.0 42.0 |

| API605-81 | 26″-60″ | Class 150、300、600 |

| ASME B 16.36(96) | 1″-24″ | Class 300、400、600、900、1500、2500 |

German Standard Series | ||

| STANDARD CODES | NOMINAL SIZE | PRESSURE GRADE |

| DIN 2630 WN | DN1200-DN2400 | 1 Bar |

| DIN 2631 WN | DN10-DN3600 | 6 Bar |

| DIN 2632 WN | DN200-DN3000 | 10 Bar |

| DIN 2633 WN | DN10-DN2000 | 16 Bar |

| DIN 2634 WN | DN200-DN1000 | 25 Bar |

| DIN 2635 WN | DN10-DN500 | 40 Bar |

| DIN 2636 WN | DN10-DN400 | 64 Bar |

| DIN 2637 WN | DN10-DN350 | 100 Bar |

| DIN 2638 WN | DN10-DN300 | 160 Bar |

| DIN 2573 PL | DN10-DN500 | 6 Bar |

| DIN 2576 PL | DN10-DN500 | 10 Bar |

| DIN 2527 PL | DN10-DN500 | 6 10 16 25 40 Bar |

| DIN 2501 WN | DN15-DN500 | 10 16 25 40 63 100 160 250 320 400 Bar |

| DIN 2566 TH | DN15-DN500 | 10 16 Bar |

| DIN 2655 PL | DN15-DN500 | 0.25 0.6 1.0 1.6 2.5 4.0 Bar |

| DIN 2656 PL | DN15-DN500 | 0.25 0.6 1.0 1.6 2.5 4.0 Bar |

Japanese Standard Series | ||

| STANDARD CODES | NOMINAL SIZE | PRESSURE GRADE |

| JIS B 2220 PL | DN10-DN400 | 5K |

| JIS B 2220 SO | DN450-DN1000 | 5K |

| JIS B 2220 PL | DN10-DN225 | 10K |

| JIS 2220 SO | DN250-DN1000 | 10K |

| JIS 2220 SO | DN10-DN1200 | 16K 20K 30K |

| JIS 2220 WN | DN15-DN400 | 30K |

National Standard Series | ||

| STANDARD CODES | NOMINAL SIZE | PRESSURE GRADE |

| GB/T 9112-9113.4-2000 | DN10-DN2000 | PN 0.25 0.6 1.0 2.5 4.0 6.3 10.0 16.0 Mpa |

| JB/T 74-86.2-94 | DN10-DN1600 | PN 0.25 0.6 1.0 2.5 4.0 6.3 10.0 16.0 20.0 Mpa |

| HG 20592-20626-97 | DN10-DN2000 | PN 0.25 0.6 1.0 2.0 2.5 4.0 5.0 6.3 10.0 11.0 15.0 16.0 25.0 26.0 42.0 Mpa |

| SH 3406-96 | DN10-DN1500 | PN 1.0 2.0 5.0 6.8 10.0 15.0 25.0 42.0 Mpa |

| GB/T 17241.1-17241.7 | DN10-DN4000 | PN 0.25 0.6 1.0 1.6 2.0 2.5 4.0 5.0 Mpa |

| GB/T 15530.1-15530.8 | DN10-DN1800 | PN 0.6 1.0 1.6 2.0 2.5 4.0 5.0 Mpa |

Power Ministry Series | ||

| STANDARD CODES | NOMINAL SIZE | PRESSURE GRADE |

| D-GD86-0510-0537 | DN15-DN2000 | PN 0.25 0.6 1.0 1.6 2.5 4.0 6.4 10.0 Mpa |

| DG0511-0541 | DN15-DN1000 | PN 0.25 0.6 1.0 1.6 2.5 4.0 6.4 10.0 20.0 32.0 Mpa |

Pressure Vessel Series | ||

| STANDARD CODES | NOMINAL SIZE | PRESSURE GRADE |

| JB/T 4701-2000 | DN300-DN2000 | PN 0.25 0.6 1.0 1.6 10.0 Mpa |

| JB/T 4702-2000 | DN300-DN3000 | PN 0.25 0.6 1.0 1.6 2.5 4.0 Mpa |

| JB/T 4703-2000 | DN300-DN2000 | PN 0.6 1.0 1.6 2.5 4.0 6.4 Mpa |

| Shipping Series | ||

| STANDARD CODES | NOMINAL SIZE | PRESSURE GRADE |

| GB573-581-76 | DN20-DN500 | PN 0.6 1.0 1.6 2.5 4.0 6.4 Mpa |

| GB2506-2507-89 | DN10-DN2000 | PN 0.25 0.6 1.0 1.6 2.5 Mpa |

| GB4450-84 | DN20-DN500 | PN 0.6 1.0 1.6 Mpa |

| GB10746-10749-89 | DN10-DN600 | PN 0.6 1.0 1.6 2.5 4.0 6.4 Mpa |

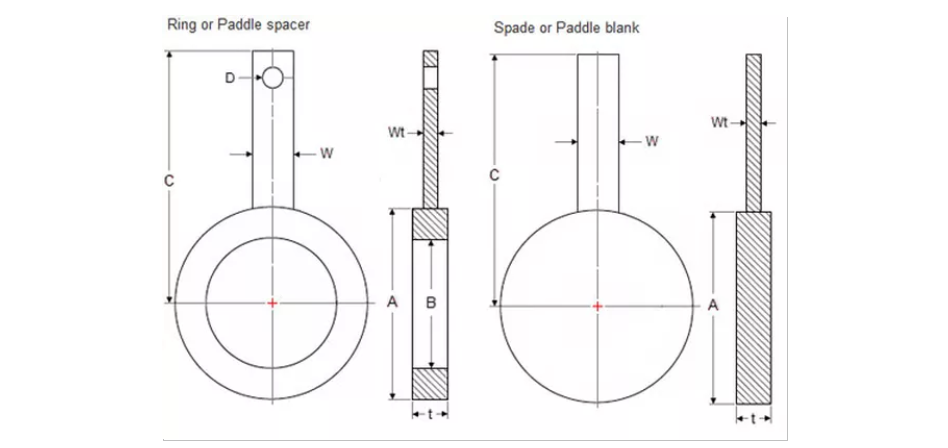

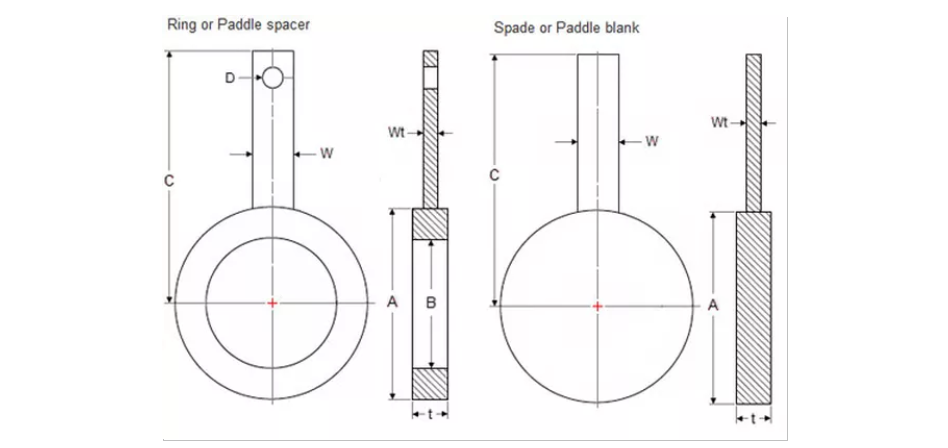

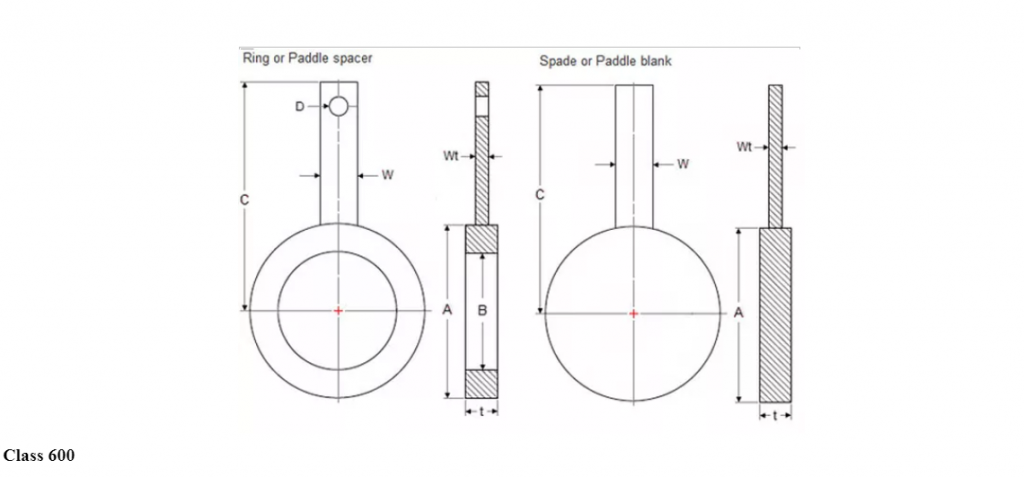

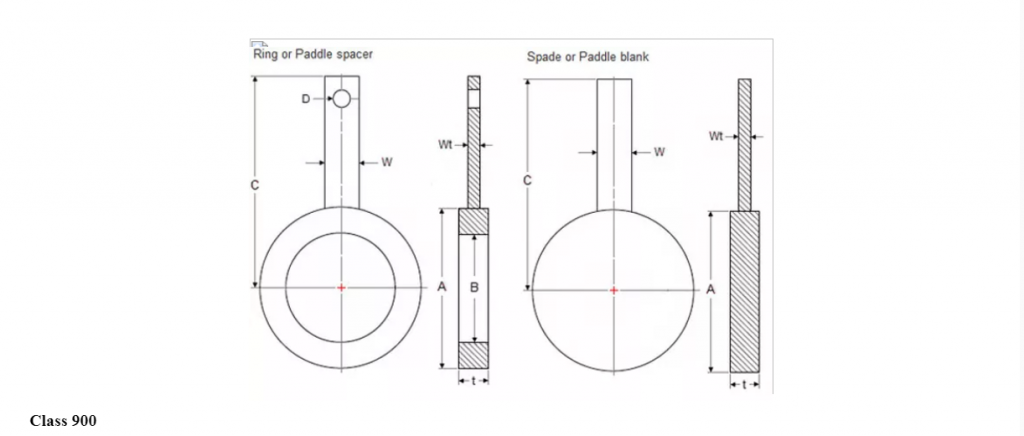

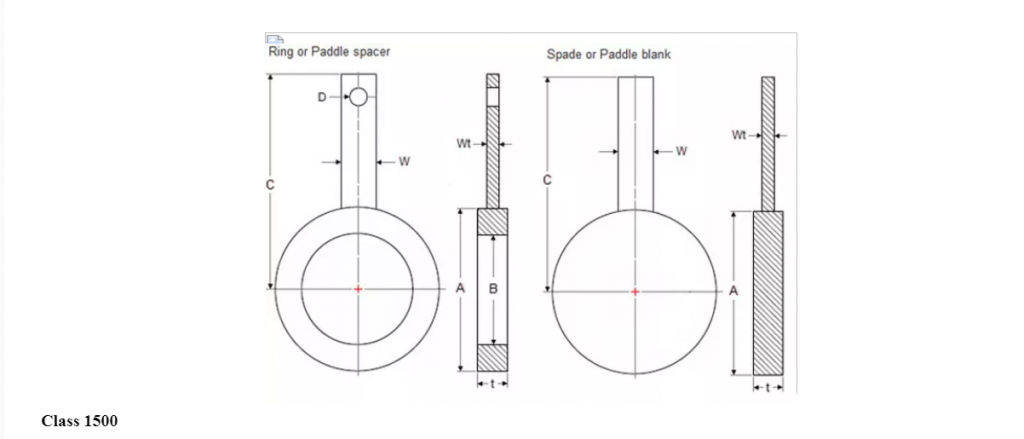

SPADES & RING SPACERS

Spades and Ring Spacers are basically the same as Spectacle Blinds, except that both are not attached to each other.

Spades and Spacers be applied in systems where maintenance is often not necessary, or in applications with large pipe sizes. Spectacle Blinds, Spades and Ring Spacers should be made from a plate or forging specification, approved for use by ASME B31.3, of essentially the same chemical composition as the mating flanges and piping involved.

Dimensions

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| 1/2 | 45 | 16 | 126 | 3 | 32 |

| 3/4 | 54 | 21 | 131 | 3 | 32 |

| 1 | 64 | 27 | 136 | 3 | 32 |

| 1¼ | 73 | 42 | 145 | 6.4 | 32 |

| 1½ | 83 | 48 | 145 | 6.4 | 32 |

| 2 | 102 | 61 | 155 | 6.4 | 32 |

| 2½ | 107 | 73 | 170 | 6.4 | 32 |

| 3 | 133 | 89 | 170 | 6.4 | 32 |

| 3½ | 159 | 102 | 202 | 9.7 | 38 |

| 4 | 172 | 114 | 202 | 9.7 | 38 |

| 5 | 194 | 141 | 225 | 9.7 | 38 |

| 6 | 219 | 168 | 225 | 12.7 | 38 |

| 8 | 276 | 219 | 267 | 12.7 | 38 |

| 10 | 337 | 273 | 322 | 15.7 | 44 |

| 12 | 406 | 324 | 357 | 19.1 | 44 |

| 14 | 448 | 356 | 378 | 19.1 | 44 |

| 16 | 511 | 406 | 410 | 22.4 | 44 |

| 18 | 546 | 457 | 427 | 25.4 | 51 |

| 20 | 603 | 508 | 455 | 28.4 | 51 |

| 24 | 714 | 610 | 512 | 31.8 | 51 |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| 1/2 | 51 | 16 | 129 | 6.4 | 32 |

| 3/4 | 64 | 21 | 136 | 6.4 | 32 |

| 1 | 70 | 27 | 139 | 6.4 | 32 |

| 1¼ | 79 | 42 | 150 | 6.4 | 32 |

| 1½ | 92 | 48 | 150 | 6.4 | 32 |

| 2 | 108 | 61 | 158 | 9.7 | 32 |

| 2½ | 127 | 73 | 177 | 9.7 | 32 |

| 3 | 146 | 89 | 177 | 9.7 | 32 |

| 3½ | 162 | 102 | 205 | 12.7 | 38 |

| 4 | 178 | 114 | 205 | 12.7 | 38 |

| 5 | 213 | 141 | 240 | 15.7 | 38 |

| 6 | 248 | 168 | 240 | 15.7 | 38 |

| 8 | 305 | 219 | 281 | 22.4 | 38 |

| 10 | 359 | 273 | 333 | 25.4 | 44 |

| 12 | 419 | 324 | 363 | 28.4 | 44 |

| 14 | 483 | 356 | 395 | 31.8 | 44 |

| 16 | 536 | 406 | 422 | 38.1 | 44 |

| 18 | 594 | 457 | 450 | 41.1 | 51 |

| 20 | 651 | 508 | 480 | 44.5 | 51 |

| 24 | 772 | 610 | 540 | 50.8 | 51 |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| 1/2 | 51 | 16 | 129 | 6.4 | 32 |

| 3/4 | 64 | 21 | 136 | 6.4 | 32 |

| 1 | 70 | 27 | 139 | 6.4 | 32 |

| 1¼ | 79 | 37 | 150 | 9.7 | 32 |

| 1½ | 92 | 43 | 150 | 9.7 | 32 |

| 2 | 108 | 55 | 158 | 9.7 | 32 |

| 2½ | 127 | 67 | 177 | 12.7 | 32 |

| 3 | 146 | 83 | 177 | 12.7 | 32 |

| 3½ | 159 | 96 | 211 | 15.7 | 38 |

| 4 | 191 | 108 | 211 | 15.7 | 38 |

| 5 | 238 | 135 | 248 | 19.1 | 38 |

| 6 | 264 | 162 | 248 | 22.4 | 38 |

| 8 | 318 | 212 | 288 | 28.4 | 38 |

| 10 | 397 | 265 | 352 | 35.1 | 44 |

| 12 | 454 | 315 | 381 | 41.1 | 44 |

| 14 | 489 | 346 | 398 | 44.5 | 44 |

| 16 | 562 | 397 | 435 | 50.8 | 44 |

| 18 | 610 | 448 | 459 | 53.8 | 51 |

| 20 | 679 | 497 | 493 | 63.5 | 51 |

| 24 | 787 | 597 | 547 | 73.2 | 51 |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| 1/2 | 60 | 16 | 134 | 6.4 | 32 |

| 3/4 | 67 | 21 | 137 | 6.4 | 32 |

| 1 | 76 | 27 | 142 | 6.4 | 32 |

| 1¼ | 86 | 37 | 151 | 9.7 | 32 |

| 1½ | 95 | 43 | 151 | 9.7 | 32 |

| 2 | 140 | 55 | 174 | 12.7 | 32 |

| 2½ | 162 | 67 | 186 | 12.7 | 32 |

| 3 | 165 | 83 | 186 | 15.7 | 32 |

| 4 | 203 | 108 | 217 | 19.1 | 38 |

| 5 | 244 | 135 | 259 | 22.4 | 38 |

| 6 | 286 | 162 | 259 | 25.4 | 38 |

| 8 | 356 | 212 | 307 | 35.1 | 38 |

| 10 | 432 | 265 | 370 | 41.1 | 44 |

| 12 | 495 | 315 | 401 | 47.8 | 44 |

| 14 | 518 | 346 | 412 | 53.8 | 44 |

| 16 | 572 | 397 | 440 | 60.5 | 44 |

| 18 | 635 | 448 | 471 | 66.5 | 51 |

| 20 | 696 | 497 | 501 | 73.2 | 51 |

| 24 | 835 | 597 | 571 | 88.9 | 51 |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| 1/2 | 61 | 16 | 135 | 6.4 | 32 |

| 3/4 | 67 | 21 | 137 | 9.7 | 32 |

| 1 | 76 | 27 | 142 | 9.7 | 32 |

| 1¼ | 86 | 35 | 151 | 9.7 | 32 |

| 1½ | 95 | 41 | 151 | 12.7 | 32 |

| 2 | 140 | 53 | 174 | 12.7 | 32 |

| 2½ | 162 | 63 | 190 | 15.7 | 32 |

| 3 | 172 | 78 | 190 | 19.1 | 32 |

| 4 | 206 | 102 | 219 | 22.4 | 38 |

| 5 | 251 | 128 | 256 | 28.4 | 38 |

| 6 | 279 | 154 | 256 | 35.1 | 38 |

| 8 | 349 | 203 | 303 | 41.1 | 38 |

| 10 | 432 | 255 | 370 | 50.8 | 44 |

| 12 | 518 | 303 | 412 | 60.5 | 44 |

| 14 | 575 | 333 | 442 | 66.5 | 44 |

| 16 | 638 | 381 | 472 | 76.2 | 44 |

| 18 | 702 | 429 | 504 | 85.9 | 51 |

| 20 | 752 | 478 | 530 | 95.3 | 51 |

| 24 | 899 | 575 | 603 | 111.3 | 51 |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

| 1/2 | 67 | 16 | 137 | 9.7 | 32 |

| 3/4 | 73 | 21 | 140 | 9.7 | 32 |

| 1 | 83 | 27 | 145 | 9.7 | 32 |

| 1¼ | 102 | 35 | 161 | 12.7 | 32 |

| 1½ | 114 | 41 | 161 | 15.7 | 32 |

| 2 | 143 | 53 | 175 | 15.7 | 32 |

| 2½ | 165 | 63 | 201 | 19.1 | 32 |

| 3 | 194 | 78 | 201 | 22.4 | 32 |

| 4 | 232 | 102 | 232 | 28.4 | 38 |

| 5 | 276 | 128 | 273 | 35.1 | 38 |

| 6 | 314 | 154 | 273 | 41.1 | 38 |

| 8 | 384 | 198 | 321 | 53.8 | 38 |

| 10 | 473 | 248 | 390 | 66.5 | 44 |

| 12 | 546 | 289 | 427 | 79.2 | 44 |

| NPS | Outside Ø A | Inside Ø B | Center to End C | Thickness t | Handle Width W |

Notes:

Dimensions are in millimeters unless otherwise indicated.

Spade Handles shall be solid with no openings.

Ring Spacer Handles shall have a single through indicator hole located near the end of the handle. The hole diameter shall not be less than 12 mm.

Wt = Thickness of the handle should be 6 mm minimum, or equal to Thickness (t) if less than 6 mm.

Spades and Ring Spacers should be made from a plate or forging specification, approved for use by ASME B31.3, of essentially the same chemical composition as the mating flanges and piping involved.

Spades & Ring Spacers according to ASME B16.48 may be used for installation between ASME B16.5 flanges

Depending on a customer specification, some dimensions can be different from what on this page is defined.

WELDO FLANGE / NIPO FLANGE

A Nipoflange is a combination of , nipolet and flange & widely used in the pipe industry like a or a nipolet for a 90° branch connection

Material Grades: ASTM A105N ASTM A350 LF2

Nickel Alloy

ASTM / ASME SB 564 UNS 2200 ( NICKEL 200 ), UNS 4400 (MONEL 400 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276) ASTM / ASME SB 160UNS 2201 (NICKEL 201 ) ASTM / ASME SB 472UNS 8020 ( ALLOY 20 / 20 CB 3)

Copper Alloy

ASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600.

ASTM / ASME SB 151 UNS NO.70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30), ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200.

Stainless Steel

ASTM / ASME SA 182 F304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel

ASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.

Carbon Steel

ASTM / ASME A 105.

ASTM / ASME A 350 LF 2.

Alloy Steel

ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91.

Nickel Alloy Standard :

ASTM / ASME SB 564 / 160 / 472

Nickel 200 – UNS N02200

Nickel 201 – UNS N02201

Monel 400 – UNS N04400

Monel K500 – UNS N05500

Inconel K600 – UNS N06600

Inconel 601 – UNS N06601

Inconel 625 – UNS N06625

Inconel 800 – UNS N08800

Inconel 800H – UNS N08810

Inconel 825 – UNS N08825

Hastelloy C276 – UNS N10276

Alloy 20 – UNS N08020

Dimensions

| Type of Olets | Nipoflange |

| Size | 1/8″ (6 NB) to 20″ (500NB) |

| Standard | MSS SP-97 |

| Class | 3000LB(SCH40,SCH80,STD,XS) 6000LB(SCH160,XXS) |

Material | Grade |

| Carbon Steel | ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70 |

Stainless Steel | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L |

| Alloy Steel | ASTM / ASME A/SA 182 F12, A182 F11, A182 F22, A182 F5, A350 LF2, A350 LF3 |