90° LONG RADIUS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

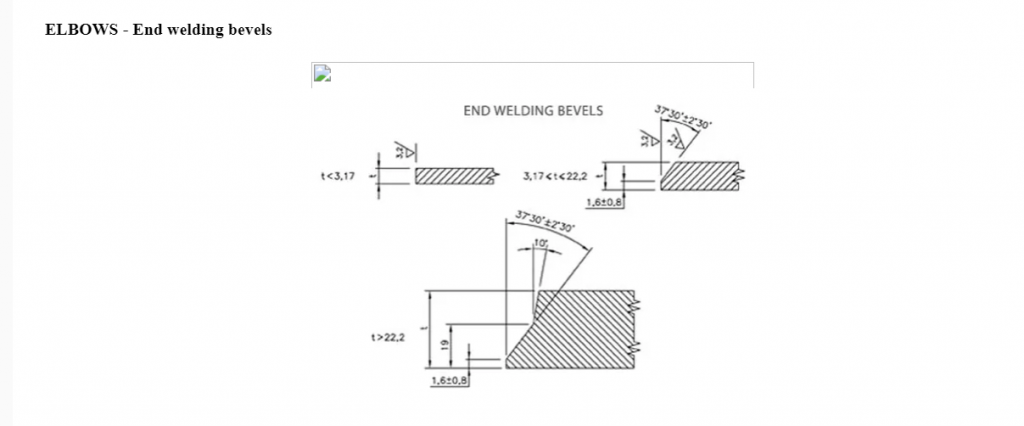

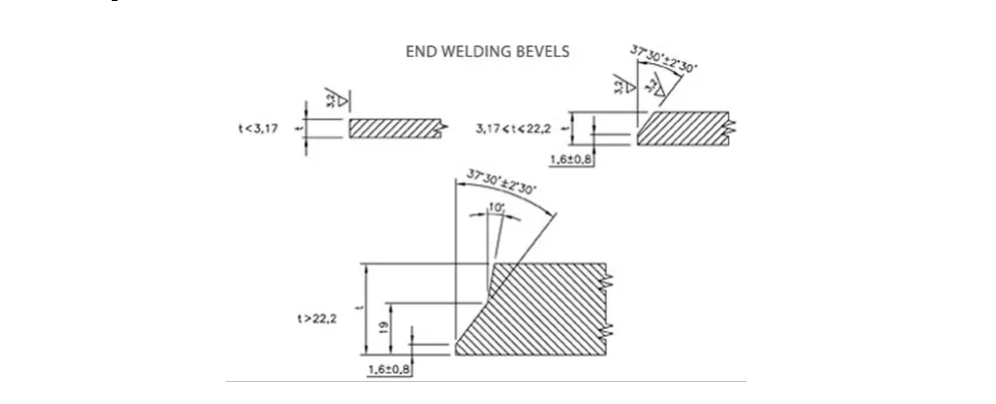

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | Diameters – from 21,3 to 711 mm. Wall Thickness – from 2 to 40 mm. |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

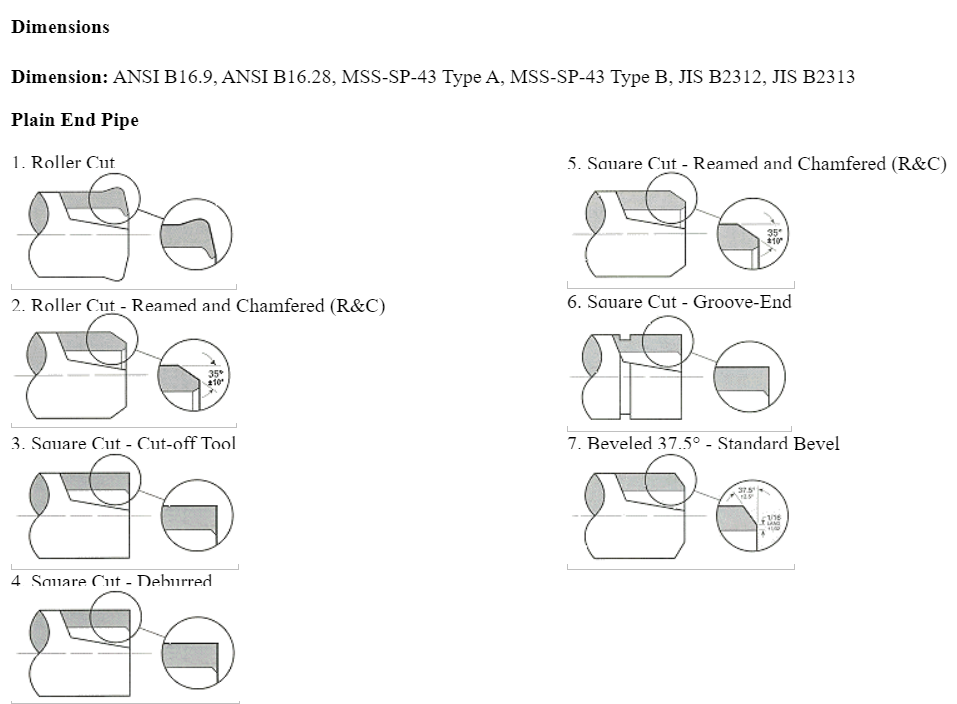

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

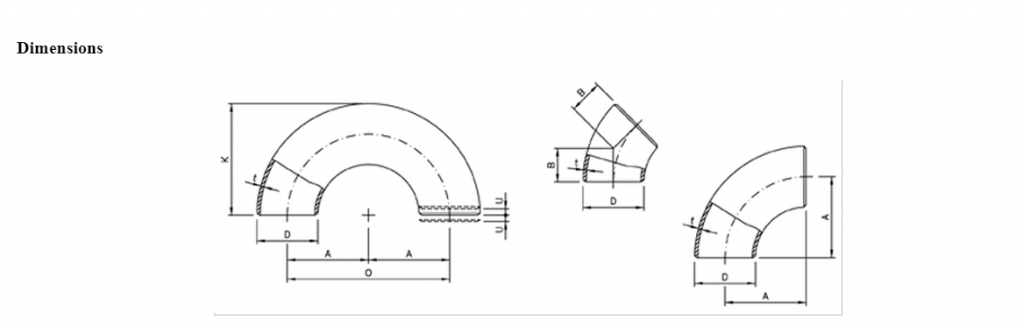

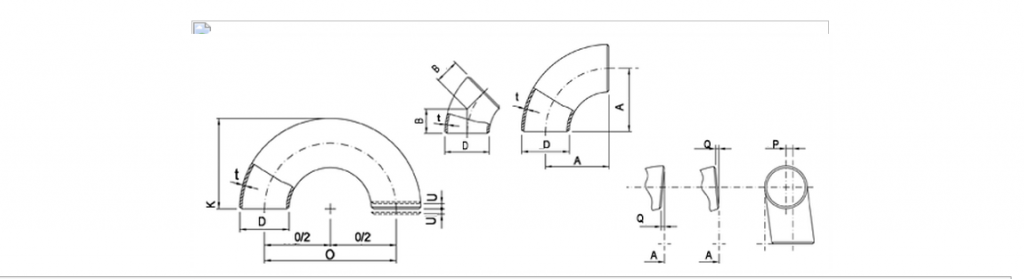

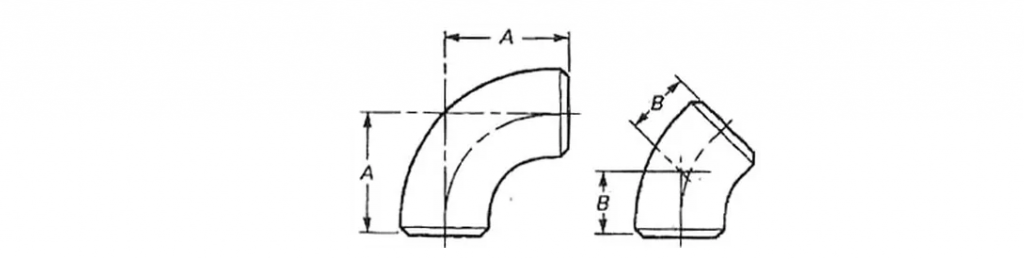

| LONG RADIUS ELBOWS (R = 1,5 ND) ANSI B 16.9 dimensions | ||||||

| inches | ND | mm | Center to center | Radius | Center to end | Back to face |

| D | O | A | B | K | ||

| 1/2 | 15 | 21,34 | 76,20 | 38,10 | 15,87 | 47,62 |

| 3/4 | 20 | 26,67 | 57,15 | 28,57 | 11,11 | 42,86 |

| 1 | 25 | 33,40 | 76,20 | 38,10 | 22,22 | 55,56 |

| 1 1/4 | 32 | 42,16 | 95,25 | 47,60 | 25,40 | 69,85 |

| 1 1/2 | 40 | 48,26 | 114,30 | 57,15 | 28,57 | 82,55 |

| 2 | 50 | 60,32 | 152,40 | 76,20 | 34,92 | 106,40 |

| 2 1/2 | 65 | 73,02 | 190,50 | 95,25 | 44,45 | 131,80 |

| 3 | 80 | 88,90 | 228,60 | 114,30 | 50,80 | 158,75 |

| 3 1/2 | 90 | 101,60 | 266,70 | 133,35 | 57,15 | 184,15 |

| 4 | 100 | 114,30 | 304,80 | 152,40 | 63,50 | 209,55 |

| 5 | 125 | 141,30 | 381,00 | 190,50 | 79,38 | 261,90 |

| 6 | 150 | 168,27 | 457,20 | 228,60 | 95,25 | 312,70 |

| 8 | 200 | 219,07 | 609,60 | 304,80 | 127,00 | 414,30 |

| 10 | 250 | 273,05 | 762,00 | 381,00 | 158,75 | 517,50 |

| 12 | 300 | 323,85 | 914,40 | 457,20 | 190,50 | 619,10 |

| 14 | 350 | 355,60 | 1066,80 | 533,40 | 222,25 | 711,20 |

| 16 | 400 | 406,40 | 1219,20 | 609,60 | 254,00 | 812,80 |

| 18 | 450 | 457,20 | 1371,60 | 685,80 | 285,74 | 914,40 |

| 20 | 500 | 508,00 | 1524,00 | 762,00 | 317,50 | 1016,00 |

| 22 | 550 | 558,80 | 1676,40 | 838,20 | 342,90 | 1117,60 |

| 24 | 600 | 609,60 | 1828,80 | 914,40 | 381,00 | 1219,20 |

| 28 | 700 | 711,20 | 2133,60 | 1066,80 | 441,90 | 1422,40 |

| Dimensions in mm. | ||||||

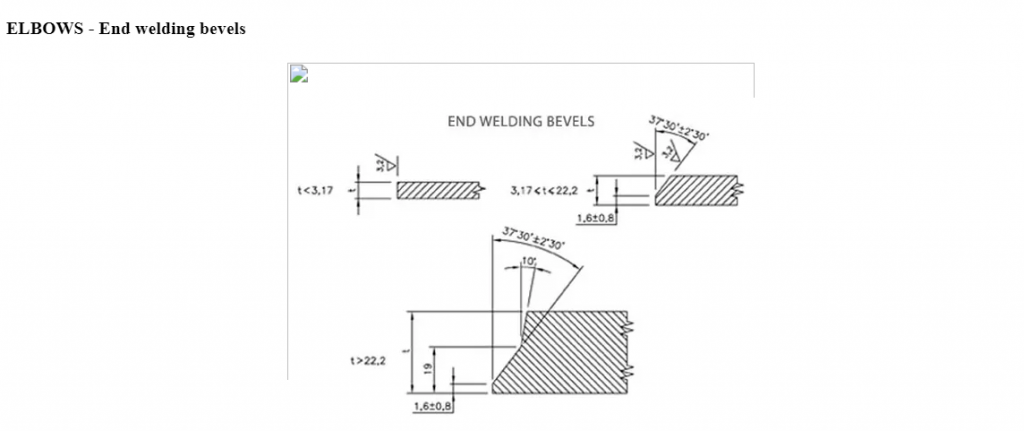

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Inside Ø at End | Wall Thickness t / t1 | Center to End Dim. A-B-C-M | Center to Center Dim. O | Back to Face Dim. K | Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

ELBOWS – Weights

| WEIGHTS OF FITTINGS | ||||||||

| NPS inches | ELBOWS LR 90° | ELBOWS SR 90° | ||||||

| Sch. 5S | Sch. 10S | Sch. 40S | Sch. 80S | Sch. 5S | Sch. 10S | Sch. 40S | Sch. 80S | |

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.90 | 1.20 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 | 0.60 | 0.90 | 1.35 | 1.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 | 0.90 | 1.35 | 2.65 | 3.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.90 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

90° SHORT RADIUS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | Diameters – from 21,3 to 711 mm. Wall Thickness – from 2 to 40 mm. |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

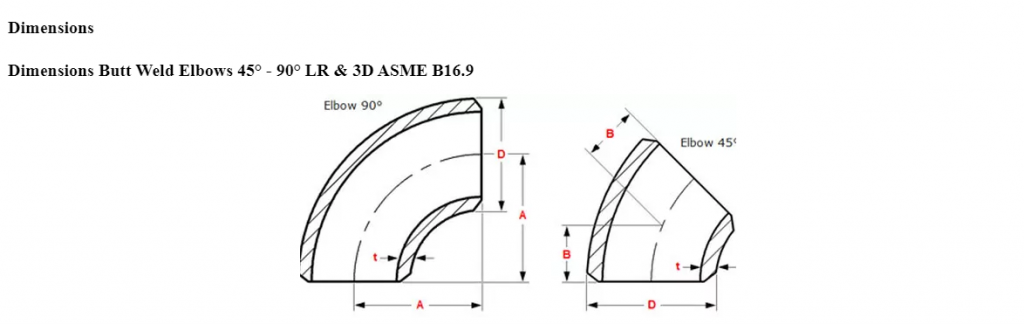

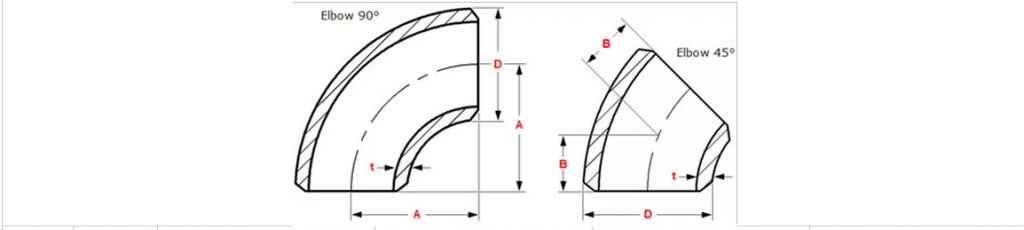

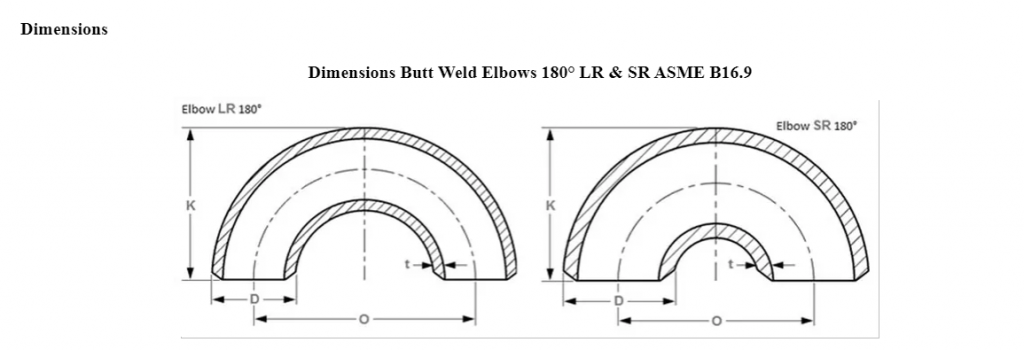

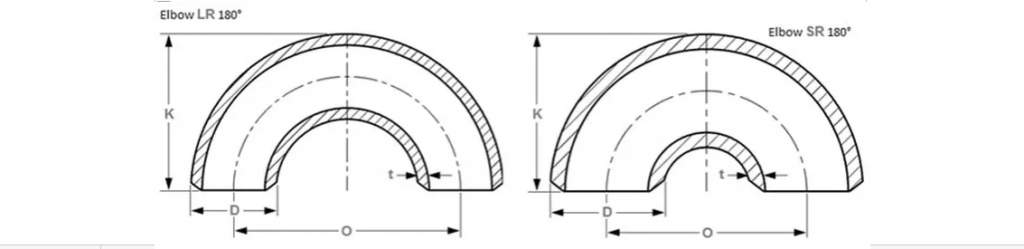

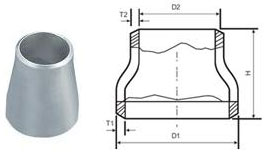

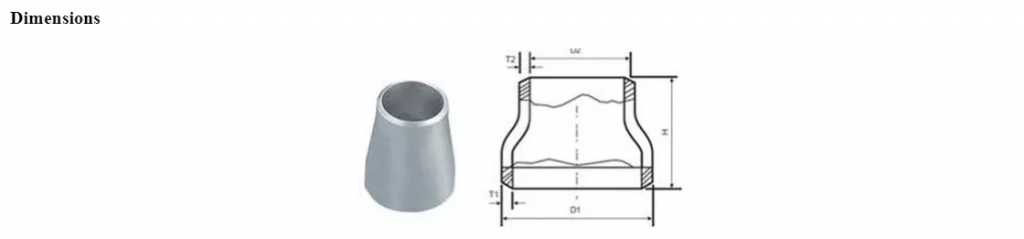

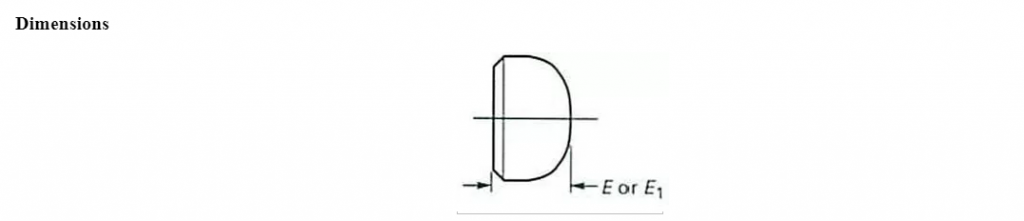

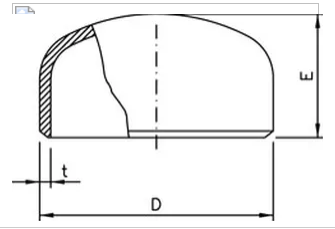

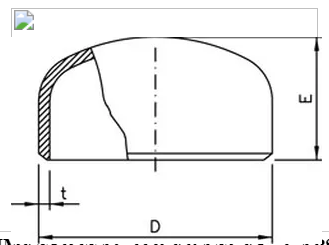

Dimensions

Dimensions Butt Weld Elbows 90° – SR ASME B16.9

| NPS | O.D. D | Center-to-End A |

| 1 | 33.4 | 25 |

| 1¼ | 42.2 | 32 |

| 1½ | 48.3 | 38 |

| 2 | 60.3 | 51 |

| 2½ | 73 | 64 |

| 3 | 88.9 | 76 |

| 3½ | 101.6 | 89 |

| NPS | O.D. D | Center-to-End A |

| NPS | O.D. D | Center-to-End A |

| 4 | 114.3 | 102 |

| 5 | 141.3 | 127 |

| 6 | 168.3 | 152 |

| 8 | 219.1 | 203 |

| 10 | 273 | 254 |

| 12 | 323.8 | 305 |

| 14 | 355.6 | 356 |

| 16 | 406.4 | 406 |

| 18 | 457 | 457 |

| 20 | 508 | 508 |

| 22 | 559 | 559 |

| 24 | 610 | 610 |

| NPS | O.D. D | Center-to-End A |

Dimensions are in millimeters unless otherwise indicated. Wall thickness (t) must be specified by customer.

Dimensional Tolerances of Butt Weld Elbows Short Radius 90° ASME B16.9

| Nominal Pipe Size | 1/2 to 2½ | 3 to 3½ | 4 | 5 to 8 | 10 to 18 | 20 to 24 | 26 to 30 | 32 to 48 |

| Outside Diameter at Bevel (D) | + 1.6 – 0.8 | 1.6 | 1.6 | + 2.4 – 1.6 | + 4 – 3.2 | + 6.4 – 4.8 | + 6.4 – 4.8 | + 6.4 – 4.8 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 | 3.2 | 4.8 | + 6.4 – 4.8 | + 6.4 – 4.8 |

| Center-to-End (A) | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 5 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||||||

Dimensional tolerances are in millimeters unless otherwise indicated and are equal ± except as noted.

Note:

MSS SP-43 only covers stainless steel buttweld fittings made for use with Schedule 5S and 10S pipe and Stub Ends suitable for use with Schedule 40S pipes.

The dimensions and dimensional tolerances defined in MSS SP-43 are substantially the same as those in ASME B16.9 specifications from NPS 1/2 – NPS 24. Except with regard to the outside diameter at the bevel.

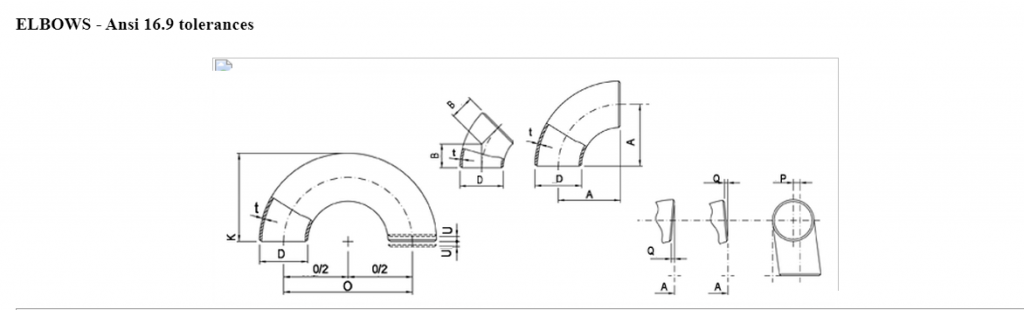

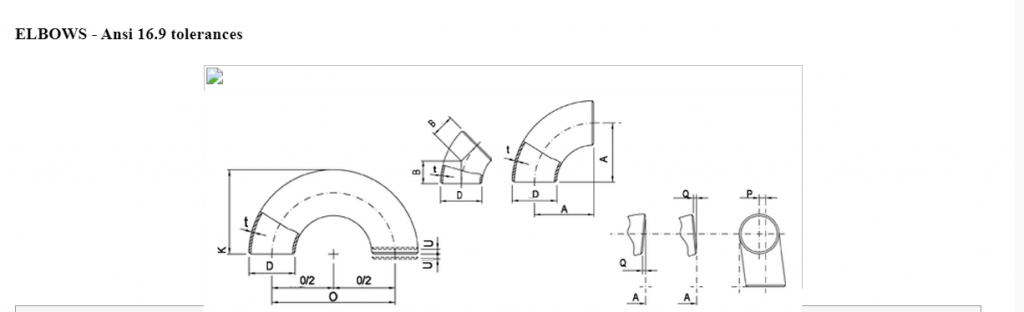

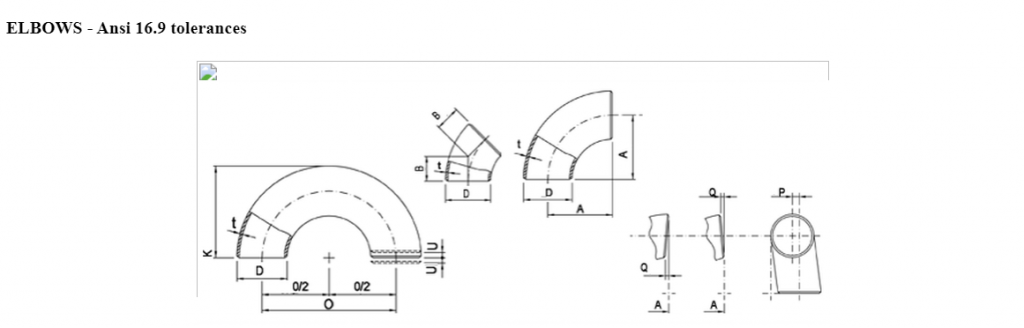

ELBOWS – Ansi 16.9 tolerances

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Inside Ø at End | Wall Thickness t / t1 | Center to End Dim. A-B-C-M | Center to Center Dim. O | Back to Face Dim. K | Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

ELBOWS – Weights

| WEIGHTS OF FITTINGS | ||||||||

| NPS inches | ELBOWS LR 90° | ELBOWS SR 90° | ||||||

| Sch. 5S | Sch. 10S | Sch. 40S | Sch. 80S | Sch. 5S | Sch. 10S | Sch. 40S | Sch. 80S | |

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.90 | 1.20 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 | 0.60 | 0.90 | 1.35 | 1.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 | 0.90 | 1.35 | 2.65 | 3.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.90 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

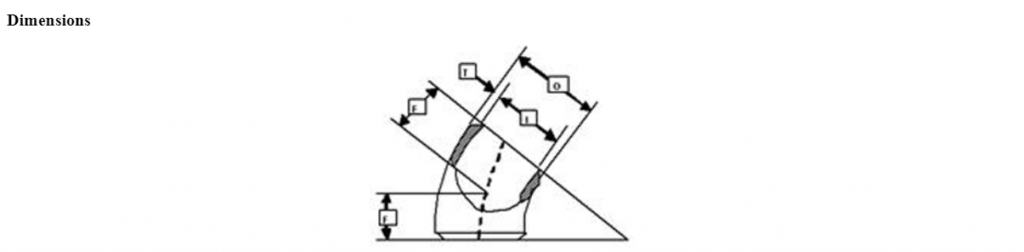

45° LONG RADIUS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | Diameters – from 21,3 to 711 mm. Wall Thickness – from 2 to 40 mm. |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

| NPS | O.D. D | 90 degrees Long Radius Center-to-End A | 45 degrees Long Radius Center-to-End B | 90 degrees 3D Center-to-End A | 45 degrees 3D Center-to-End B |

| 1/2 | 21.3 | 38 | 16 | – | – |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3½ | 101.6 | 133 | 57 | 267 | 111 |

| NPS | O.D. D | 90 degrees Long Radius Center-to-End A | 45 degrees Long Radius Center-to-End B | 90 degrees 3D Center-to-End A | 45 degrees 3D Center-to-End B |

| NPS | O.D. D | 90 degrees Long Radius Center-to-End A | 45 degrees Long Radius Center-to-End B | 90 degrees 3D Center-to-End A | 45 degrees 3D Center-to-End B |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 964 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

| NPS | O.D. D | 90 degrees Long Radius Center-to-End A | 45 degrees Long Radius Center-to-End B | 90 degrees 3D Center-to-End A | 45 degrees 3D Center-to-End B |

Dimensions are in millimeters unless otherwise indicated. Wall thickness (t) must be specified by customer.

Dimensional Tolerances of Butt Weld Elbows – 45° & 90° – LR & 3D – ASME B16.9 –

| Nominal Pipe Size | 1/2 to 2½ | 3 to 3½ | 4 | 5 to 8 | 10 to 18 | 20 to 24 | 26 to 30 | 32 to 48 |

| Outside Diameter at Bevel (D) | + 1.6 – 0.8 | 1.6 | 1.6 | + 2.4 – 1.6 | + 4 – 3.2 | + 6.4 – 4.8 | + 6.4 – 4.8 | + 6.4 – 4.8 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 | 3.2 | 4.8 | + 6.4 – 4.8 | + 6.4 – 4.8 |

| Center-to-End LR (A/B) | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 5 |

| Center-to-End 3D (A/B) | 3 | 3 | 3 | 3 | 3 | 3 | 6 | 6 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||||||

Dimensional tolerances are in millimeters unless otherwise indicated and are equal ± except as noted.

45° SHORT RADIUS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | Diameters – from 21,3 to 711 mm. Wall Thickness – from 2 to 40 mm. |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

Nom. Pipe Size | Pipe Sched. or No. | Center- to-end Dimen. | Outside Dia. | Inside Dia. | Wall Thick. | Approx. Weight (lb.) |

| F | OD | ID | T | |||

| STANDARD WEIGHT | ||||||

| 1/2 | 40 | 5/8 | 0.840 | 0.622 | 0.109 | 0.1 |

| 3/4 | 40 | 7/16 | 1.050 | 0.824 | 0.113 | 0.1 |

| 1 | 40 | 7/8 | 1.315 | 1.049 | 0.133 | 0.2 |

| 1 1/4 | 40 | 1 | 1.660 | 1.380 | 0.140 | 0.4 |

| 1 1/2 | 40 | 1 1/8 | 1.900 | 1.610 | 0.145 | 0.5 |

| 2 | 40 | 1 3/8 | 2.375 | 2.067 | 0.154 | 0.9 |

| 2 1/2 | 40 | 1 3/4 | 2.875 | 2.469 | 0.203 | 1.5 |

| 3 | 40 | 2 | 3.500 | 3.068 | 0.216 | 2.5 |

| 3 1/2 | 40 | 2 1/4 | 4.000 | 3.548 | 0.226 | 3.5 |

| 4 | 40 | 2 1/2 | 4.500 | 4.026 | 0.237 | 4.8 |

| 5 | 40 | 3 1/8 | 5.563 | 5.047 | 0.258 | 7.8 |

| 6 | 40 | 3 3/4 | 6.625 | 6.065 | 0.280 | 12 |

| 8 | 40 | 5 | 8.625 | 7.981 | 0.322 | 23 |

| 10 | 40 | 6 1/4 | 10.750 | 10.020 | 0.365 | 42 |

| 12 | – | 7 1/2 | 12.750 | 12.000 | 0.375 | 61 |

| 14 | 30 | 8 3/4 | 14.000 | 13.250 | 0.375 | 79 |

| 16 | 30 | 10 | 16.000 | 15.250 | 0.375 | 103 |

| 18 | – | 11 1/4 | 18.000 | 17.250 | 0.375 | 132 |

| 20 | 20 | 12 1/2 | 20.000 | 19.250 | 0.375 | 160 |

| 22 | 20 | 13 1/2 | 22.000 | 21.250 | 0.375 | 195 |

| 24 | 20 | 15 | 24.000 | 23.250 | 0.375 | 238 |

| EXTRA STRONG | ||||||

Nom. Pipe Size | Pipe Sched. or No. | Center- to-end Dimen. | Outside Dia. | Inside Dia. | Wall Thick. | Approx. Weight (lb.) |

| F | OD | ID | T | |||

| 1/2 | 80 | 5/8 | 0.840 | 0.546 | 0.147 | 0.2 |

| 3/4 | 80 | 7/16 | 1.050 | 0.742 | 0.154 | 0.3 |

| 1 | 80 | 7/8 | 1.315 | 0.957 | 0.179 | 0.4 |

| 1 1/4 | 80 | 1 | 1.660 | 1.278 | 0.191 | 0.5 |

| 1 1/2 | 80 | 1 1/8 | 1.900 | 1.500 | 0.200 | 0.6 |

| 2 | 80 | 1 3/8 | 2.375 | 1.939 | 0.218 | 1.1 |

| 2 1/2 | 80 | 1 3/4 | 2.875 | 2.323 | 0.276 | 2.1 |

| 3 | 80 | 2 | 3.500 | 2.900 | 0.300 | 3.5 |

| 3 1/2 | 80 | 2 1/4 | 4.000 | 3.364 | 0.318 | 4.8 |

| 4 | 80 | 2 1/2 | 4.500 | 3.826 | 0.337 | 6.5 |

| 5 | 80 | 3 1/8 | 5.563 | 4.813 | 0.375 | 11 |

| 6 | 80 | 3 3/4 | 6.625 | 5.761 | 0.432 | 18 |

| 8 | 80 | 5 | 8.625 | 7.625 | 0.500 | 35 |

| 10 | 60 | 6 1/4 | 10.750 | 9.750 | 0.500 | 56 |

| 12 | – | 7 1/2 | 12.750 | 11.750 | 0.500 | 80 |

| 14 | – | 8 3/4 | 14.000 | 13.000 | 0.500 | 100 |

| 16 | 40 | 10 | 16.000 | 15.000 | 0.500 | 131 |

| 18 | – | 11 1/4 | 18.000 | 17.000 | 0.500 | 172 |

| 20 | 30 | 12 1/2 | 20.000 | 19.000 | 0.500 | 210 |

| 22 | 30 | 13 1/2 | 22.000 | 21.000 | 0.500 | 259 |

| 24 | – | 15 | 24.000 | 23.000 | 0.500 | 302 |

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Inside Ø at End | Wall Thickness t / t1 | Center to End Dim. A-B-C-M | Center to Center Dim. O | Back to Face Dim. K | Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

ELBOWS – Weights

| WEIGHTS OF FITTINGS | ||||||||

| NPS inches | ELBOWS LR 90° | ELBOWS SR 90° | ||||||

| Sch. 5S | Sch. 10S | Sch. 40S | Sch. 80S | Sch. 5S | Sch. 10S | Sch. 40S | Sch. 80S | |

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.90 | 1.20 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 | 0.60 | 0.90 | 1.35 | 1.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 | 0.90 | 1.35 | 2.65 | 3.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.90 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

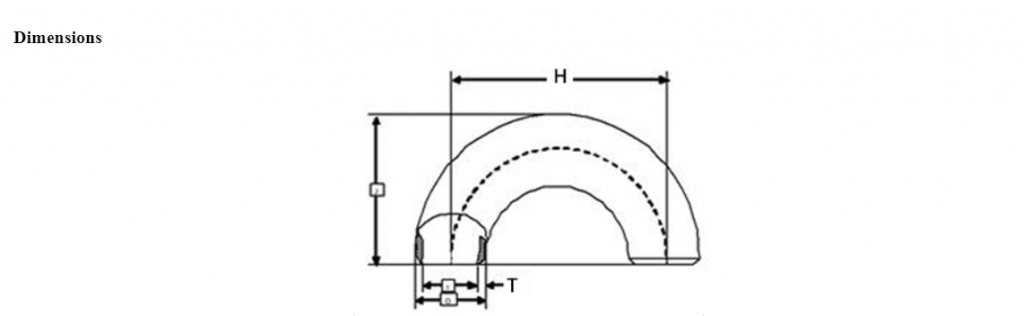

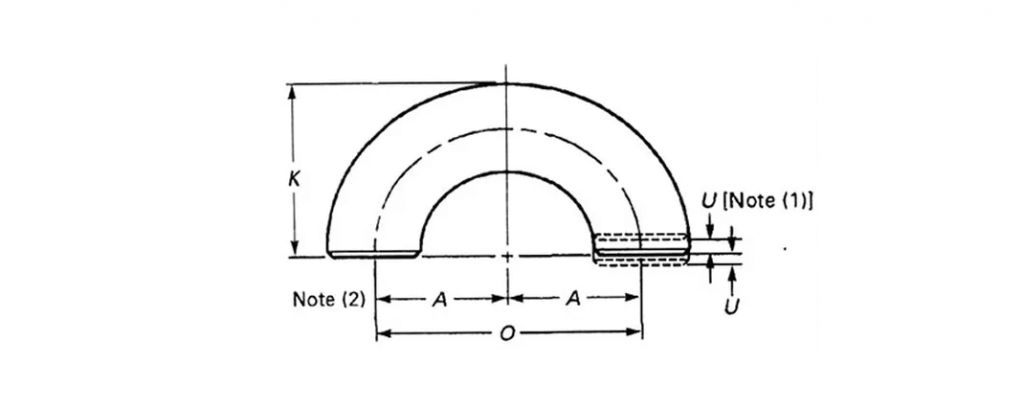

180° LONG RADIUS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | Diameters – from 21,3 to 711 mm. Wall Thickness – from 2 to 40 mm. |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

Nom. Pipe Size | Pipe Sched. or No. | Center- to-Center Dimen. | Back- to- Face | Outside Dia. | Inside Dia. | Wall Thick. | Approx. Weight (lb.) |

| H | J | OD | ID | T | |||

| STANDARD WEIGHT | |||||||

| 1/2 | 40 | 3 | 1 7/8 | 0.840 | 0.622 | 0.109 | 0.3 |

| 3/4 | 40 | 2 1/2 | 1 11/16 | 1.050 | 0.824 | 0.113 | 0.3 |

| 1 | 40 | 3 | 2 3/16 | 1.315 | 1.049 | 0.133 | 0.7 |

| 1 1/4 | 40 | 3 3/4 | 2 3/4 | 1.660 | 1.380 | 0.140 | 1 |

| 1 1/2 | 40 | 4 1/2 | 3 1/4 | 1.900 | 1.610 | 0.145 | 1.5 |

| 2 | 40 | 6 | 4 3/16 | 2.375 | 2.067 | 0.154 | 3 |

| 2 1/2 | 40 | 7 1/2 | 5 3/16 | 2.875 | 2.469 | 0.203 | 6 |

| 3 | 40 | 9 | 6 1/4 | 3.500 | 3.068 | 0.216 | 9 |

| 3 1/2 | 40 | 10 1/2 | 7 1/4 | 4.000 | 3.548 | 0.226 | 12 |

| 4 | 40 | 12 | 8 1/4 | 4.500 | 4.026 | 0.237 | 17 |

| 5 | 40 | 15 | 10 5/16 | 5.563 | 5.047 | 0.258 | 28 |

| 6 | 40 | 18 | 12 5/16 | 6.625 | 6.065 | 0.280 | 46 |

| 8 | 40 | 24 | 16 5/16 | 8.625 | 7.981 | 0.322 | 90 |

| 10 | 40 | 30 | 20 3/8 | 10.750 | 10.020 | 0.365 | 156 |

| 12 | – | 36 | 24 3/8 | 12.750 | 12.000 | 0.375 | 236 |

| 14 | 30 | 42 | 28 | 14.000 | 13.250 | 0.375 | 294 |

| 16 | 30 | 48 | 32 | 16.000 | 15.250 | 0.375 | 404 |

| 18 | – | 54 | 36 | 18.000 | 17.250 | 0.375 | 512 |

| 20 | 20 | 60 | 40 | 20.000 | 19.250 | 0.375 | 617 |

| 24 | 20 | 72 | 48 | 24.000 | 23.250 | 0.375 | 886 |

| EXTRA STRONG | |||||||

| 1/2 | 80 | 3 | 1 7/8 | 0.840 | 0.546 | 0.147 | 0.5 |

| 3/4 | 80 | 2 1/2 | 1 11/16 | 1.050 | 0.742 | 0.154 | 0.5 |

| 1 | 80 | 3 | 2 3/16 | 1.315 | 0.957 | 0.179 | 1 |

| 1 1/4 | 80 | 3 3/4 | 2 3/4 | 1.660 | 1.278 | 0.191 | 1.5 |

| 1 1/2 | 80 | 4 1/2 | 3 1/4 | 1.900 | 1.500 | 0.200 | 2 |

| 2 | 80 | 6 | 4 3/16 | 2.375 | 1.939 | 0.218 | 4 |

| 2 1/2 | 80 | 7 1/2 | 5 3/16 | 2.875 | 2.323 | 0.276 | 7.5 |

| 3 | 80 | 9 | 6 1/4 | 3.500 | 2.900 | 0.300 | 12 |

| 3 1/2 | 80 | 10 1/2 | 7 1/4 | 4.000 | 3.364 | 0.318 | 17 |

| 4 | 80 | 12 | 8 1/4 | 4.500 | 3.826 | 0.337 | 23 |

| 5 | 80 | 15 | 10 5/16 | 5.563 | 4.813 | 0.375 | 40 |

| 6 | 80 | 18 | 12 5/16 | 6.625 | 5.761 | 0.432 | 67 |

| 8 | 80 | 24 | 16 5/16 | 8.625 | 7.625 | 0.500 | 138 |

| 10 | 60 | 30 | 20 3/8 | 10.750 | 9.750 | 0.500 | 215 |

| 12 | – | 36 | 24 3/8 | 12.750 | 11.750 | 0.500 | 300 |

| 14 | – | 42 | 28 | 14.000 | 13.000 | 0.500 | 376 |

| 16 | 40 | 48 | 32 | 16.000 | 15.000 | 0.500 | 524 |

| 18 | – | 54 | 36 | 18.000 | 17.000 | 0.500 | 676 |

| 20 | 30 | 60 | 40 | 20.000 | 19.000 | 0.500 | 824 |

| 24 | – | 72 | 48 | 24.000 | 20.000 | 0.500 | 1183 |

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Inside Ø at End | Wall Thickness t / t1 | Center to End Dim. A-B-C-M | Center to Center Dim. O | Back to Face Dim. K | Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

180° SHORT RADIUS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | Diameters – from 21,3 to 711 mm. Wall Thickness – from 2 to 40 mm. |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

| NPS | O.D. D | 180° Long Radius | 180° Short Radius | ||

| Center to Center O | Back to Face K | Center to Center O | Back to Face K | ||

| 1/2 | 21.3 | 76 | 48 | – | – |

| 3/4 | 26.7 | 76 | 51 | – | – |

| 1 | 33.4 | 76 | 56 | 51 | 41 |

| 1¼ | 42.2 | 95 | 70 | 64 | 52 |

| 1½ | 48.3 | 114 | 83 | 76 | 62 |

| 2 | 60.3 | 152 | 106 | 102 | 81 |

| 2½ | 73 | 190 | 132 | 127 | 100 |

| 3 | 88.9 | 229 | 159 | 152 | 121 |

| 3½ | 101.6 | 267 | 184 | 178 | 140 |

| NPS | O.D. D | 180° Long Radius | 180° Short Radius | ||

| Center to Center O | Back to Face K | Center to Center O | Back to Face K | ||

| NPS | O.D. D | 180° Long Radius | 180° Short Radius | ||

| Center to Center O | Back to Face K | Center to Center O | Back to Face K | ||

| 4 | 114.3 | 305 | 210 | 203 | 159 |

| 5 | 141.3 | 381 | 262 | 254 | 197 |

| 6 | 168.3 | 457 | 313 | 305 | 237 |

| 8 | 219.1 | 610 | 414 | 406 | 313 |

| 10 | 273 | 762 | 518 | 508 | 391 |

| 12 | 323.8 | 914 | 619 | 610 | 467 |

| 14 | 355.6 | 1067 | 711 | 711 | 533 |

| 16 | 406.4 | 1219 | 813 | 813 | 610 |

| 18 | 457 | 1372 | 914 | 914 | 686 |

| 20 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 559 | 1676 | 1118 | 1118 | 838 |

| 24 | 610 | 1829 | 1219 | 1219 | 914 |

| NPS | O.D. D | 180° Long Radius | 180° Short Radius | ||

| Center to Center O | Back to Face K | Center to Center O | Back to Face K | ||

Dimensions are in millimeters unless otherwise indicated. Wall thickness (t) must be specified by customer.

Dimensional Tolerances of Butt Weld Elbows 180° LR and SR ASME B16.9

| Nominal Pipe Size | 1/2 to 2½ | 3 to 3½ | 4 | 5 to 8 | 10 to 18 | 20 to 24 |

| Outside Diameter at Bevel (D) | + 1.6 – 0.8 | 1.6 | 1.6 | + 2.4 – 1.6 | + 4 – 3.2 | + 6.4 – 4.8 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 | 3.2 | 4.8 |

| Center to Center (O) | 6 | 6 | 6 | 6 | 10 | 10 |

| Back to Face (K) | 6 | 6 | 6 | 6 | 6 | 6 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||||

Dimensional tolerances are in millimeters unless otherwise indicated and are equal ± except as noted.

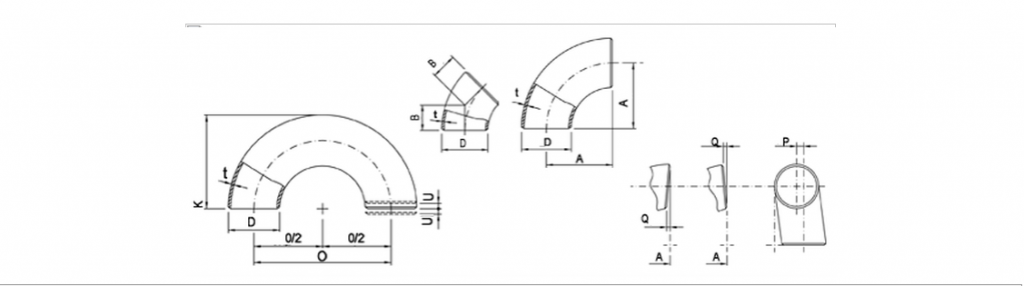

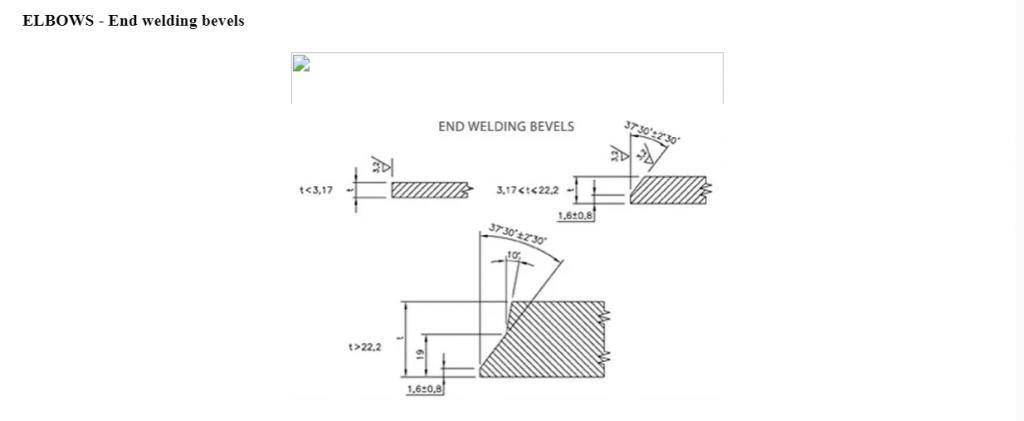

ELBOWS – Ansi 16.9 tolerances

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Inside Ø at End | Wall Thickness t / t1 | Center to End Dim. A-B-C-M | Center to Center Dim. O | Back to Face Dim. K | Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

1D ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

Dimensions

| Material: | Stainless Steel |

|---|---|

| Export Markets: | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

Manufacturing Process

All BW-fittings are cold formed, annealed, pickled and shot blasted. The starting material is either plate or pipe (seamless or welded).

Standards

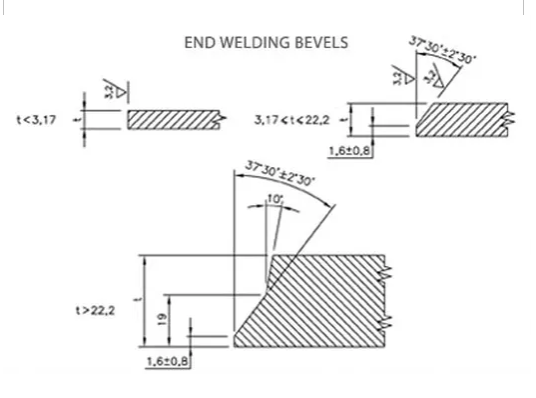

Butt welding fittings are manufactured in accordance with ANSI B 16.9 for dimensions and tolerances, ANSI B 16.9/B 16.25 for end preparation as well as ASTM A 403 or other applicable Standards for manufacturing and testing requirements. Fittings can also be manufactured conforming to customer specifications.

1.5D ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

3D ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

5D ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

Specifications :

RANGE : 2″NB TO 18″ NB ANSI B 16.9 IN

SCH : 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS

TYPE : SEAMLESS / WELDED/ FABRICATED

Form : Long radius Bend, Piggable Bend, Hot bend, With R=3D, 5D, 6D, 8D, 10D & Customized Bend

Offer : Minimum Wall Thinning rate & Ovality, No Wrinkles

Materials

Stainless Steel 5D Bend

ASTM A 403 WP TP304,H,L,316,H,L,Ti,309 310, 317L, 321, 347, 904L

Duplex Stainless Steel 5D Bend

ASTM A 815 UNS S31803, S32760, S31500

Alloy Steel 5D Bend

ASTM A 234 WP-P5, P9, P11, P12, P21, P22 & P91

Carbon Steel 5D Bend

ASTM A 234 WPB

Low Temperature Carbon Steel 5D Bend

ASTM A 234 WPB

Nickel Alloy 5D Bend :

Standard: ASTM / ASME SB 336

UNS 10276 HASTELLOY C 276 Bend

UNS 2200 NICKEL 200 Bend

UNS 2201 NICKEL 201 Bend

UNS 4400 MONEL 400 Bend

UNS 8020 ALLOY 20 Bend

UNS 8825 INCONEL 825 Bend

UNS 6600 INCONEL 600 Bend

UNS 6601 INCONEL 601 Bend

UNS 6625 INCONEL 625 Bend

VALUE ADDED SERVICES

Hot Dip Galvanizing

Epoxy Coating

Tags 5D Bend

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

SEAMLESS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

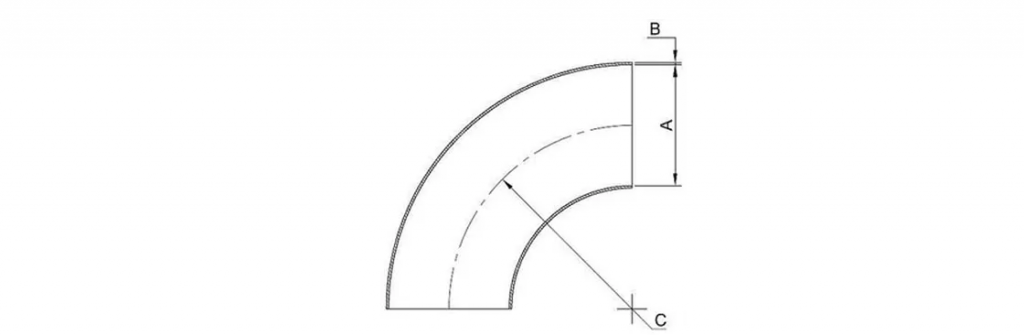

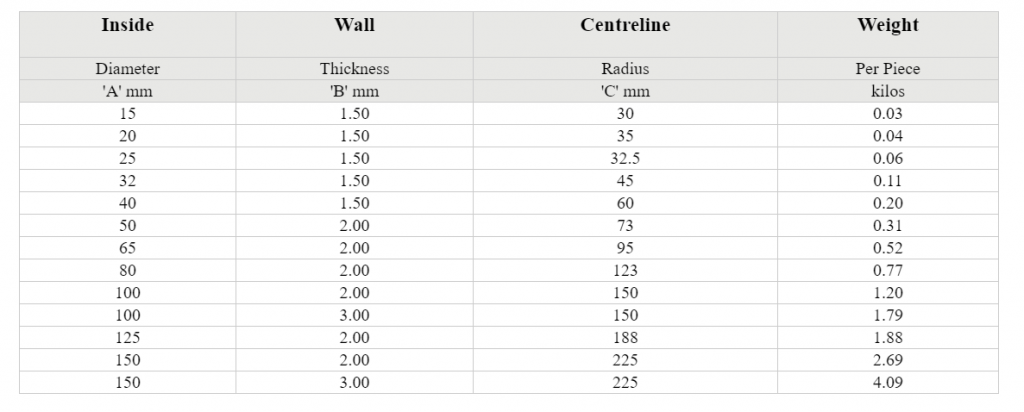

DIMENSIONS OF SEAMLESS BUTT WELDING ELBOWS

FACTORY-MADE WROUGHT BUTTWELDING FITTINGS

| Nominal Pip Size (NPS) | DN | Outside Diameter at Bevel | Center- to-End | ||

| 45º Elbow B | 90º Elbow A | ||||

| Long Radius | Long Radius | Short Radius | |||

| 1/2 | 21.3 | 16 | 38 | ||

| 3/4 | 26.7 | 19 | 38 | ||

| 1 | 25 | 33.4 | 22 | 38 | 25 |

| 1-1/4 | 32 | 42.2 | 25 | 48 | 32 |

| 1-1/2 | 40 | 48.3 | 28 | 57 | 38 |

| 2 | 50 | 60.3 | 35 | 76 | 51 |

| 2-1/2 | 65 | 73.0 | 45 | 95 | 64 |

| 3 | 80 | 88.9 | 51 | 114 | 76 |

| 3-1/2 | 90 | 101.6 | 57 | 133 | 89 |

| 4 | 100 | 114.3 | 64 | 152 | 102 |

| 5 | 125 | 141.3 | 79 | 191 | 127 |

| 6 | 150 | 168.3 | 95 | 229 | 152 |

| 8 | 200 | 219.1 | 127 | 305 | 203 |

| 10 | 250 | 273.0 | 159 | 381 | 254 |

| 12 | 300 | 323.8 | 191 | 457 | 305 |

| 14 | 350 | 355.6 | 222 | 533 | 356 |

| 16 | 400 | 406.4 | 254 | 610 | 406 |

| 18 | 450 | 457 | 286 | 686 | 457 |

| 20 | 500 | 508 | 318 | 762 | 508 |

| 22 | 550 | 559 | 343 | 838 | 559 |

| 24 | 600 | 610 | 381 | 914 | 610 |

WELDED ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

| Nominal Pipe Size (NPS) | DN | Outside Diameter at Bevel | Center- to-Center O | Back-to-Face K |

| 1 | 25 | 33.4 | 51 | 41 |

| 1-1/4 | 32 | 42.2 | 64 | 52 |

| 1-1/2 | 404 | 8.3 | 76 | 62 |

| 2 | 50 | 60.3 | 102 | 81 |

| 2-1/2 | 65 | 73.0 | 127 | 100 |

| 3 | 80 | 88.9 | 152 | 121 |

| 3-1/2 | 90 | 101.6 | 178 | 140 |

| 4 | 100 | 114.3 | 203 | 159 |

| 5 | 125 | 141.3 | 254 | 197 |

| 6 | 150 | 168.3 | 305 | 237 |

| 8 | 200 | 219.1 | 406 | 313 |

| 10 | 250 | 273.0 | 508 | 391 |

| 12 | 300 | 323.8 | 610 | 467 |

| 14 | 350 | 355.6 | 711 | 533 |

| 16 | 400 | 406.4 | 813 | 610 |

| 18 | 450 | 457 | 914 | 686 |

| 20 | 500 | 508 | 1016 | 762 |

| 22 | 550 | 559 | 1118 | 838 |

| 24 | 600 | 610 | 1219 | 914 |

NOTES:

(a). All dimensions are in millimeters.

(b). Dimension A is equal to one-half of dimension O.

SEAMLESS BUTTWELDING 180° RETURNS

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

Dimensions

FACTORY-MADE WROUGHT BUTTWELDING FITTINGS

DIMENSIONS OF 180ºRETURN

| Nominal Pip Size (NPS) | DN | Outside Diameter at Bevel | Center- to-Center D | Back-to-Face K | ||

| Long Radius | Short Radius | Long Radius | Short Radius | |||

| 1/2 | 15 | 21.3 | 76 | 48 | ||

| 3/4 | 20[Note(3)] | 26.7 | 76 | 51 | ||

| 1 | 25 | 33.4 | 76 | 51 | 56 | 41 |

| 1-1/4 | 32 | 42.2 | 95 | 64 | 70 | 52 |

| 1-1/2 | 40 | 48.3 | 114 | 76 | 83 | 62 |

| 2 | 50 | 60.3 | 152 | 102 | 106 | 81 |

| 2-1/2 | 65 | 73.0 | 190 | 127 | 132 | 100 |

| 3 | 80 | 88.9 | 229 | 152 | 159 | 121 |

| 3-1/2 | 90 | 101.6 | 267 | 178 | 184 | 140 |

| 4 | 100 | 114.3 | 305 | 203 | 210 | 159 |

| 5 | 125 | 141.3 | 381 | 254 | 262 | 197 |

| 6 | 150 | 168.3 | 457 | 305 | 313 | 237 |

| 8 | 200 | 219.1 | 610 | 406 | 414 | 313 |

| 10 | 250 | 273.0 | 762 | 508 | 518 | 391 |

| 12 | 300 | 323.8 | 914 | 610 | 619 | 467 |

| 14 | 350 | 355.6 | 1067 | 711 | 711 | 533 |

| 16 | 400 | 406.4 | 1219 | 813 | 813 | 610 |

| 18 | 450 | 457 | 1372 | 914 | 914 | 686 |

| 20 | 500 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 550 | 559 | 1676 | 1118 | 1118 | 838 |

| 24 | 600 | 610 | 1829 | 1219 | 1219 | 914 |

(1) See Table 2 for tolerances for alignment of ends U.

(2) Dimension A is equal to one-half of dimension O.

(3) O and K dimensions of 55mm and 43mm,respectively,mat be furnished for NPS 3/4(DN20)at the manufacture’s option.

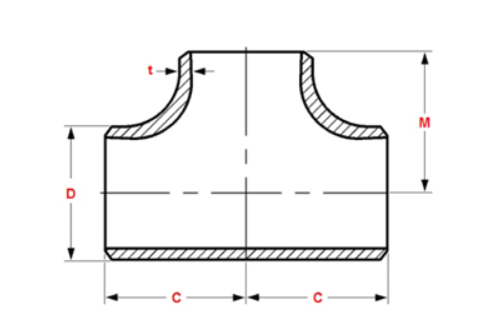

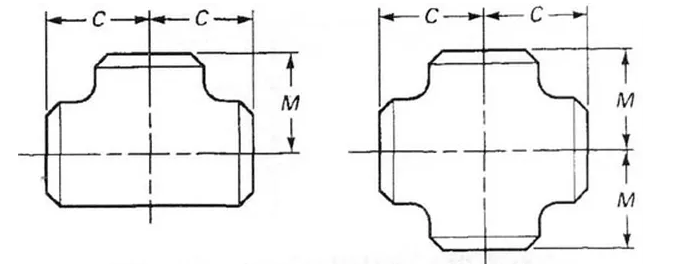

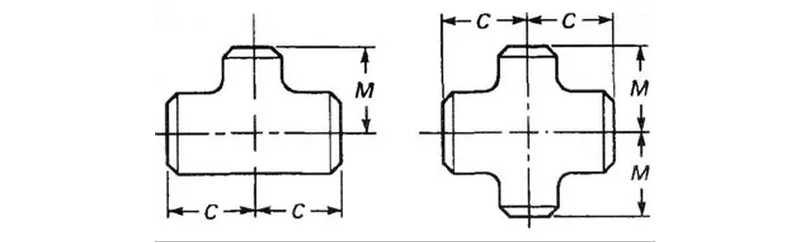

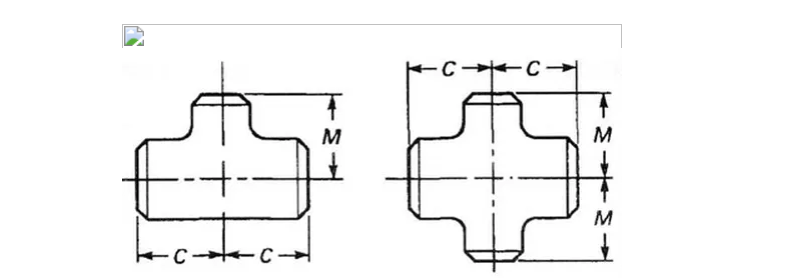

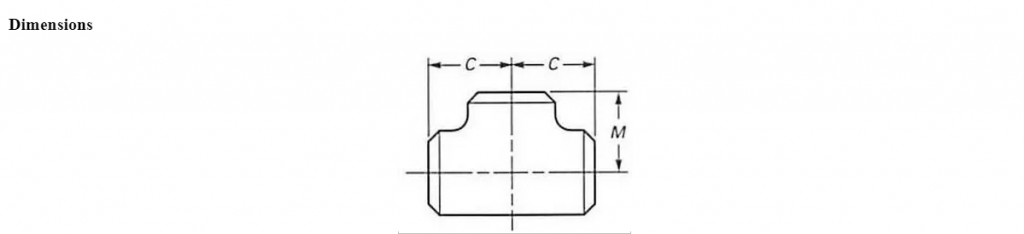

STRAIGHT TEE & CROSSES

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

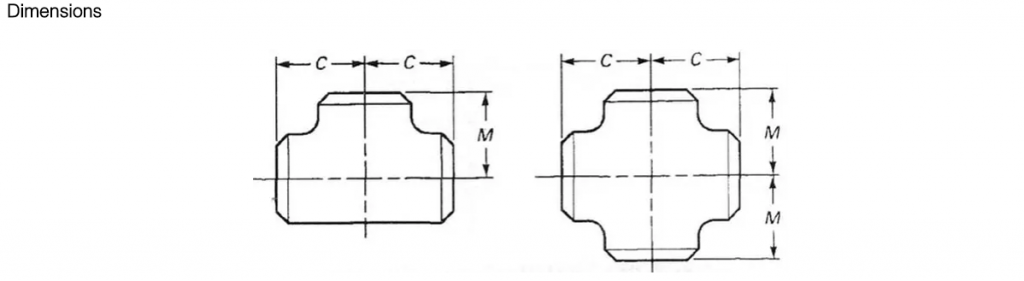

Dimensions

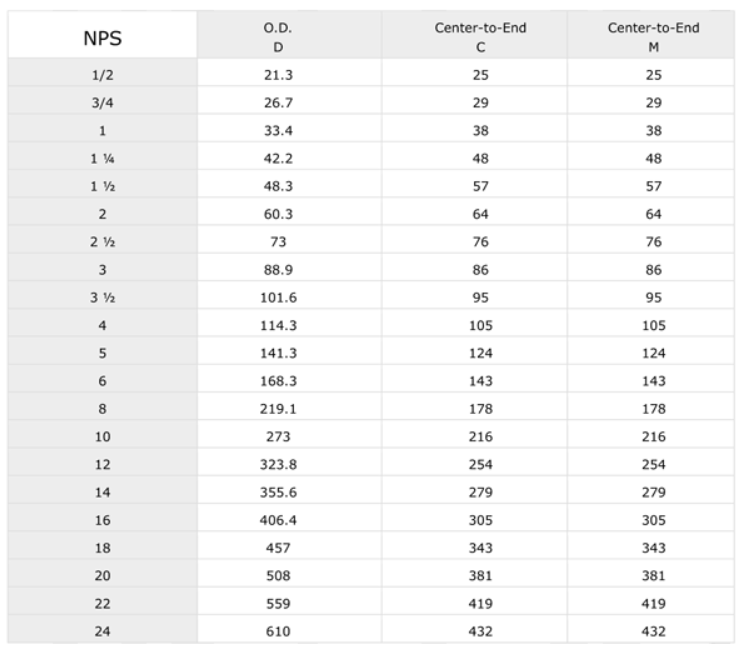

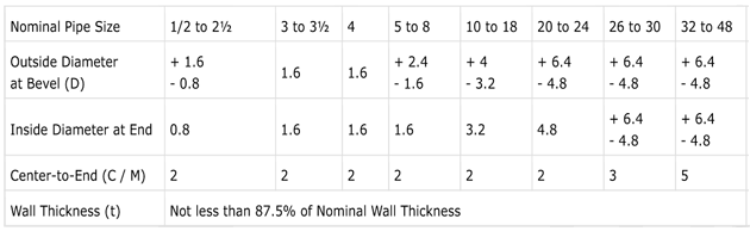

Dimensions butt welded Straight Tees – NPS 1/2 – 48 according to ASME B16.9

Dimensions are in millimeters unless otherwise indicated. Wall thickness (t) must be specified by customer.

DIMENSIONAL TOLERANCES STRAIGHT TEES ACCORDING TO ASME B16.9

Dimensional tolerances are in millimeters unless otherwise indicated and are equal ± except as noted.

Note:

MSS SP-43 only covers stainless steel buttweld fittings made for use with Schedule 5S and 10S pipe and Stub Ends suitable for use with Schedule 40S pipe, as defined in ASME B36.19M. The dimensions and tolerances defined in MSS SP-43 are substantially the same as those in ASME B16.9 specifications from NPS 1/2 up to NPS 24. Except

with regard to the outside diameter at the bevel.

FACTORY-MADE WROUGHT BUTTWELDING FITTINGS – ASME B16.9

DIMENSIONS OF STRAIGHT TEES AND CROSSES

| Nominal Pipe Size (NPS) | DN | Outside Diameter at Bevel | Center- to-End | |

Run.C | Outlet. M[Notes(1) and (2)] | |||

| 1/2 | 15 | 21.3 | 25 | 25 |

| 3/4 | 20 | 26.7 | 29 | 29 |

| 1 | 25 | 33.4 | 38 | 38 |

| 1-1/4 | 32 | 42.2 | 48 | 48 |

| 1-1/2 | 40 | 48.3 | 57 | 57 |

| 2 | 50 | 60.3 | 64 | 64 |

| 2-1/2 | 65 | 73.0 | 76 | 76 |

| 3 | 80 | 88.9 | 86 | 86 |

| 3-1/2 | 90 | 101.6 | 95 | 95 |

| 4 | 100 | 114.3 | 105 | 105 |

| 5 | 125 | 141.3 | 124 | 124 |

| 6 | 150 | 168.3 | 143 | 143 |

| 8 | 200 | 219.1 | 178 | 178 |

| 10 | 250 | 273.0 | 216 | 216 |

| 12 | 300 | 323.8 | 254 | 254 |

| 14 | 350 | 355.6 | 279 | 279 |

| 16 | 400 | 406.4 | 305 | 305 |

| 18 | 450 | 457 | 343 | 343 |

| 20 | 500 | 508 | 381 | 381 |

| 22 | 550 | 559 | 419 | 419 |

| 24 | 600 | 610 | 432 | 432 |

| 26 | 650 | 660 | 495 | 495 |

| 28 | 700 | 711 | 521 | 521 |

| 30 | 750 | 762 | 559 | 559 |

| 32 | 800 | 813 | 597 | 597 |

| 34 | 850 | 864 | 635 | 635 |

| 36 | 900 | 914 | 673 | 673 |

| 38 | 950 | 965 | 711 | 711 |

| 40 | 1000 | 1016 | 749 | 749 |

| 42 | 1050 | 1067 | 762 | 711 |

| 44 | 1100 | 1118 | 813 | 762 |

| 46 | 1150 | 1168 | 851 | 800 |

| 48 | 1200 | 1219 | 889 | 838 |

GENERAL NOTES: All dimensions are in millimeters.

(a). Outlet dimension M for NPS 26(DN 650) and large is recommended but not required.

(b). Dimensions applicable to crosses NPS 24(DN 600) and smaller.

REDUCING OUTLET TEES AND REDUCING OUTLET CROSSES

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

Dimensions

ASME B16.9

FACTORY-MADE WROUGHT BUTTWELDING FITTINGS

DIMENSIONS OF REDUCING OUTLET TEES AND REDUCING OUTLET CROSSES

| Nominal Pipe Size (NPS) | DN | Outlet Diameter at Bevel | Center- to-End | ||

| Run | Outlet | Run.C | Outlet. M[Notes(1)] | ||

| 1/2*1/2*3/8 | 15*15*10 | 21.3 | 17.3 | 25 | 25 |

| 1/2*1/2*1/4 | 15*15*8 | 21.3 | 13.7 | 25 | 25 |

| 3/4*3/4*1/2 | 20*20*15 | 26.7 | 21.3 | 29 | 29 |

| 3/4*3/4*3/8 | 20*20*10 | 26.7 | 17.3 | 29 | 29 |

| 1*1*3/4 | 25*25*20 | 33.4 | 26.7 | 38 | 38 |

| 1*1*1/2 | 25*25*15 | 33.4 | 21.3 | 38 | 38 |

| 1-1/4*1-1/4*1 | 32*32*25 | 42.2 | 33.4 | 48 | 48 |

| 1-1/4*1-1/4*3/4 | 32*32*20 | 42.2 | 26.7 | 48 | 48 |

| 1-1/4*1-1/4*1/2 | 32*32*15 | 42.2 | 21.3 | 48 | 48 |

| 1-1/2*1-1/2*1-1/4 | 40*40*32 | 48.3 | 42.2 | 57 | 57 |

| 1-1/2*1-1/2*1 | 40*40*25 | 48.3 | 33.4 | 57 | 57 |

| 1-1/2*1-1/2*3/4 | 40*40*20 | 48.3 | 26.7 | 57 | 57 |

| 1-1/2*1-1/2*1/2 | 40*40*15 | 48.3 | 21.3 | 57 | 57 |

| 2*2*1-1/2 | 50*50*40 | 60.3 | 48.3 | 64 | 60 |

| 2*2*1-1/4 | 50*50*32 | 60.3 | 42.2 | 64 | 57 |

| 2*2*1 | 50*50*25 | 60.3 | 33.4 | 64 | 51 |

| 2*2*3/4 | 50*50*20 | 60.3 | 73.0 | 64 | 44 |

| 2-1/2*2-1/2*2 | 65*65*50 | 73.0 | 60.3 | 76 | 70 |

| 2-1/2*2-1/2*1-1/2 | 65*65*40 | 73.0 | 48.3 | 76 | 67 |

| 2-1/2*2-1/2*1-1/4 | 65*65*32 | 73.0 | 42.2 | 76 | 64 |

| 2-1/2*2-1/2*1 | 65*65*25 | 73.0 | 88.9 | 76 | 57 |

| 3*3*2-1/2 | 80*80*65 | 88.9 | 73.0 | 86 | 83 |

| 3*3*2 | 80*80*50 | 88.9 | 60.3 | 86 | 76 |

| 3*3*1-1/2 | 80*80*40 | 88.9 | 48.3 | 86 | 73 |

| 3*3*1-1/4 | 80*80*32 | 88.9 | 101.6 | 86 | 70 |

| 3-1/2*3-1/2*3 | 90*90*80 | 101.6 | 88.9 | 95 | 92 |

| 3-1/2*3-1/2*2-1/2 | 90*90*65 | 101.6 | 73.0 | 95 | 89 |

| 3-1/2*3-1/2*2 | 90*90*50 | 101.6 | 60.3 | 95 | 83 |

| 3-1/2*3-1/2*1-1/2 | 90*90*40 | 101.6 | 48.3 | 95 | 79 |

| 4*4*3-1/2 | 100*100*90 | 114.3 | 101.6 | 105 | 102 |

| 4*4*3 | 100*100*80 | 114.3 | 88.9 | 105 | 98 |

| 4*4*2-1/2 | 100*100*65 | 114.3 | 73.0 | 105 | 95 |

| 4*4*2 | 100*100*50 | 114.3 | 60.3 | 105 | 89 |

| 4*4*1-1/2 | 100*100*40 | 114.3 | 48.3 | 105 | 86 |

| 5*5*4 | 125*125*100 | 141.3 | 114.3 | 124 | 117 |

| 5*5*3-1/2 | 125*125*90 | 141.3 | 101.6 | 124 | 114 |

| 5*5*3 | 125*125*80 | 141.3 | 88.9 | 124 | 111 |

| 5*5*2-1/2 | 125*125*65 | 141.3 | 73.6 | 124 | 108 |

| 5*5*2 | 125*125*50 | 141.3 | 60.3 | 124 | 105 |

GENERAL NOTE: All dimensions are in millimeter.

NOTE: Outlet dimension M for run sizes NPS 14(DN350) and larger is recommended but not required.

DIMENSIONS OF REDUCING OUTLET TEES AND REDUCING OUTLET CROSSES

| Nominal Pipe Size (NPS) | DN | Outlet Diameter at Bevel | Center-to-End | ||

| Run | Outlet | Run.C | Outlet. M[Notes(1)] | ||

| 6*6*5 | 150* 150*125 | 168.3 | 114.3 | 143 | 137 |

| 6*6*4 | 150*150*100 | 168.3 | 141.3 | 143 | 130 |

| 6*6*3-1/2 | 150*150*90 | 168.3 | 101.6 | 143 | 127 |

| 6*6*3 | 150*150*80 | 168.3 | 88.9 | 143 | 124 |

| 6*6*2-1/2 | 150*150*65 | 168.3 | 73.0 | 143 | 121 |

| 8*8*6 | 200*200*150 | 219.1 | 168.3 | 178 | 168 |

| 8*8*5 | 200*200*125 | 219.1 | 141.3 | 178 | 162 |

| 8*8*4 | 200*200*100 | 219.1 | 114.3 | 178 | 156 |

| 8*8*3-1/2 | 200*200*90 | 219.1 | 101.6 | 178 | 152 |

| 10*10*8 | 250*250*200 | 273.0 | 219.1 | 216 | 203 |

| 10*10*6 | 250*250*150 | 273.0 | 168.3 | 216 | 194 |

| 10*10*5 | 250*250*125 | 273.0 | 141.3 | 216 | 191 |

| 10*10*4 | 250*250*100 | 273.0 | 114.3 | 216 | 184 |

| 12*12*10 | 300*300*250 | 323.8 | 273.0 | 254 | 241 |

| 12*12*8 | 300*300*200 | 323.8 | 219.1 | 254 | 229 |

| 12*12*6 | 300*300*150 | 323.8 | 168.3 | 254 | 219 |

| 12*12*5 | 300*300*125 | 323.8 | 141.3 | 254 | 216 |

| 14*14*12 | 350*350*300 | 355.6 | 323.8 | 279 | 270 |

| 14*14*10 | 350*350*250 | 355.6 | 273.0 | 279 | 257 |

| 14*14*8 | 350*350*200 | 355.6 | 219.1 | 279 | 248 |

| 14*14*6 | 350*350*150 | 355.6 | 168.3 | 279 | 238 |

| 16*16*14 | 400*400*350 | 406.4 | 355.6 | 305 | 305 |

| 16*16*12 | 400*400*300 | 406.4 | 323.8 | 305 | 295 |

| 16*16*10 | 400*400*250 | 406.4 | 273.0 | 305 | 283 |

| 16*16*8 | 400*400*200 | 406.4 | 219.1 | 305 | 273 |

| 16*16*6 | 400*400*150 | 406.4 | 168.3 | 305 | 264 |

| 18*18*16 | 450*450*400 | 457 | 406.4 | 343 | 330 |

| 18*18*14 | 450*450*350 | 457 | 355.6 | 343 | 330 |

| 18*18*12 | 450*450*300 | 457 | 323.8 | 343 | 321 |

| 18*18*10 | 450*450*250 | 457 | 273.0 | 343 | 308 |

| 18*18*8 | 450*450*200 | 457 | 219.1 | 343 | 298 |

| 20*20*18 | 500*500*450 | 508 | 457 | 381 | 368 |

| 20*20*16 | 500*500*400 | 508 | 406.4 | 381 | 356 |

| 20*20*14 | 500*500*350 | 508 | 355.6 | 381 | 356 |

| 20*20*12 | 500*500*300 | 508 | 323.8 | 381 | 346 |

| 20*20*10 | 500*500*250 | 508 | 273.0 | 381 | 333 |

| 20*20*8 | 500*500*200 | 508 | 219.1 | 381 | 324 |

| 22*22*20 | 550*550*500 | 559 | 508 | 419 | 406 |

| 22*22*18 | 550*550*450 | 559 | 457 | 419 | 394 |

| 22*22*16 | 550*550*400 | 559 | 406.4 | 419 | 381 |

| 22*22*14 | 550*550*350 | 559 | 355.6 | 419 | 381 |

| 22*22*12 | 550*550*300 | 559 | 323.8 | 419 | 371 |

| 22*22*10 | 550*550*250 | 559 | 273.0 | 419 | 359 |

| 24*24*22 | 600*600*550 | 610 | 559 | 432 | 432 |

| 24*24*20 | 600*600*500 | 610 | 508 | 432 | 432 |

| 24*24*18 | 600*600*450 | 610 | 457 | 432 | 419 |

| 24*24*16 | 600*600*400 | 610 | 406.4 | 432 | 406 |

| 24*24*14 | 600*600*350 | 610 | 355.6 | 432 | 406 |

| 24*24*12 | 600*600*300 | 610 | 323.8 | 432 | 397 |

| 24*24*10 | 600*600*250 | 610 | 273.0 | 432 | 384 |

| 26*26*24 | 650*650*600 | 660 | 610 | 495 | 483 |

| 26*26*22 | 650*650*550 | 660 | 559 | 495 | 470 |

| 26*26*20 | 650*650*500 | 660 | 508 | 495 | 457 |

| 26*26*18 | 650*650*450 | 660 | 457 | 495 | 444 |

| 26*26*16 | 650*650*400 | 660 | 406.4 | 495 | 432 |

| 26*26*14 | 650*650*350 | 660 | 355.6 | 495 | 432 |

| 26*26*12 | 650*650*300 | 660 | 323.8 | 495 | 432 |

| 28*28*26 | 700*700*650 | 711 | 660 | 521 | 422 |

| 28*28*24 | 700*700*600 | 711 | 610 | 521 | 521 |

| 28*28*22 | 700*700*550 | 711 | 559 | 521 | 508 |

| 28*28*20 | 700*700*500 | 711 | 508 | 521 | 495 |

| 28*28*18 | 700*700*450 | 711 | 457 | 521 | 483 |

| 28*28*16 | 700*700*400 | 711 | 406.4 | 521 | 470 |

| 28*28*14 | 700*700*350 | 711 | 355.6 | 521 | 457 |

| 28*28*12 | 700*700*300 | 711 | 323.8 | 521 | 457 |

| 30*30*28 | 750*750*700 | 762 | 711 | 559 | 448 |

| 30*30*26 | 750*750*650 | 762 | 660 | 559 | 546 |

| 30*30*24 | 750*750*600 | 762 | 610 | 559 | 546 |

| 30*30*22 | 750*750*550 | 762 | 559 | 559 | 533 |

| 30*30*20 | 750*750*500 | 762 | 508 | 559 | 521 |

| 30*30*18 | 750*750*450 | 762 | 457 | 559 | 508 |

| 30*30*16 | 750*750*400 | 762 | 406.4 | 559 | 495 |

| 30*30*14 | 750*750*350 | 762 | 355.6 | 559 | 483 |

| 30*30*12 | 750*750*300 | 762 | 323.8 | 559 | 473 |

| 30*30*10 | 750*750*250 | 762 | 273.0 | 559 | 460 |

| 32*32*30 | 800*800*750 | 813 | 762 | 597 | 584 |

| 32*32*28 | 800*800*700 | 813 | 711 | 597 | 572 |

| 32*32*26 | 800*800*650 | 813 | 660 | 597 | 572 |

| 32*32*24 | 800*800*600 | 813 | 610 | 597 | 559 |

| 32*32*22 | 800*800*550 | 813 | 559 | 597 | 546 |

| 32*32*20 | 800*800*500 | 813 | 508 | 597 | 533 |

| 32*32*18 | 800*800*450 | 813 | 457 | 597 | 521 |

| 32*32*16 | 800*800*400 | 813 | 406.4 | 597 | 508 |

| 32*32*14 | 800*800*350 | 813 | 355.6 | 597 | 508 |

| 34*34*32 | 850*850*800 | 813 | 813 | 635 | 622 |

| 34*34*30 | 850*850*750 | 813 | 762 | 635 | 610 |

| 34*34*28 | 850*850*700 | 813 | 711 | 635 | 597 |

| 34*34*26 | 850*850*650 | 813 | 660 | 635 | 597 |

| 34*34*24 | 850*850*600 | 813 | 610 | 635 | 584 |

| 34*34*22 | 850*850*550 | 813 | 559 | 635 | 572 |

| 34*34*20 | 850*850*500 | 813 | 508 | 635 | 559 |

| 34*34*18 | 850*850*450 | 813 | 457 | 635 | 546 |

| 34*34*16 | 850*850*400 | 813 | 406.4 | 635 | 533 |

GENERAL NOTE: All dimensions are in millimeter.

note: Outlet dimension M for run sizes NPS 14(DN350) and larger is recommended but not required.

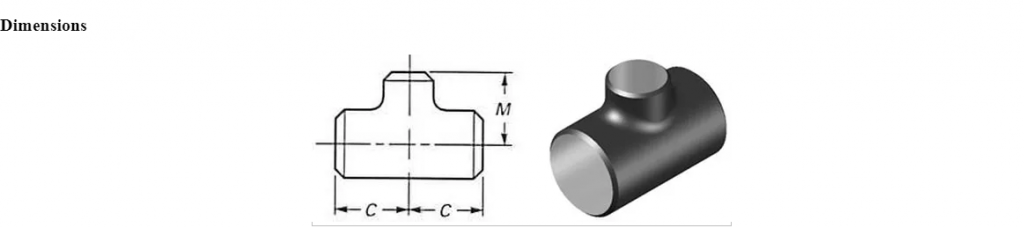

EQUAL TEE

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

| Nominal Pipe Size | Outside diameter at bevel | Center-to-End | |

|---|---|---|---|

| Run (C) | Outlet(M) | ||

| 1/2″ | 21.3 | 25 | 25 |

| 3/4″ | 26.7 | 29 | 29 |

| 1″ | 33.4 | 38 | 38 |

| 1 1/4″ | 42.2 | 48 | 48 |

| 1 1/2″ | 48.3 | 57 | 57 |

| 2″ | 60.3 | 64 | 64 |

| 2 1/2″ | 73.0 | 76 | 76 |

| 3″ | 88.9 | 86 | 86 |

| 3 1/2″ | 101.6 | 95 | 95 |

| 4″ | 114.3 | 105 | 105 |

| 5″ | 141.3 | 124 | 124 |

| 6″ | 168.3 | 143 | 143 |

| 8″ | 219.1 | 178 | 178 |

| 10″ | 273.0 | 216 | 216 |

| 12″ | 323.8 | 254 | 254 |

| 14″ | 355.6 | 279 | 279 |

| 16″ | 406.4 | 305 | 305 |

| 18″ | 457.0 | 343 | 343 |

| 20″ | 508.0 | 381 | 381 |

| 22″ | 559.0 | 419 | 419 |

| 24″ | 610.0 | 432 | 432 |

The dimensions are in millimeters

Source : ASME B16.9 – 2007

REDUCING TEE

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | Outside diameter : 1/2″ à 24″ Thickness : SCH 5S, 10S, 40S (STD), 80S (XS), 160, XXS |

| Nominal Pipe Size | Outside diameter at bevel | Center-to-End | |||

|---|---|---|---|---|---|

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

| 1/2″ | 1/4″ 3/8″ | 21.3 | 13.7 17.3 | 25 | 25 |

| 3/4″ | 3/8″ 1/2″ | 26.7 | 17.3 21.3 | 29 | 29 |

| 1″ | 1/2″ 3/4″ | 33.4 | 21.3 26.7 | 38 | 38 |

| 1 1/4″ | 1/2″ 3/4″ 1″ | 42.2 | 21.3 26.7 33.4 | 48 | 48 |

| 1 1/2″ | 1/2″ 3/4″ 1″ 1 1/4″ | 48.3 | 21.3 26.7 33.4 42.2 | 57 | 57 |

| 2″ | 3/4″ 1″ 1 1/4″ 1 1/2″ | 60.3 | 26.7 33.4 42.2 48.3 | 64 | 44 51 57 60 |

| 2 1/2″ | 1″ 1 1/4″ 1 1/2″ 2″ | 73.0 | 33.4 42.2 48.3 60.3 | 76 | 57 64 67 70 |

| 3″ | 1 1/4″ 1 1/2″ 2″ 2 1/2″ | 88.9 | 42.2 48.3 60.3 73.0 | 86 | 70 73 76 83 |

| 3 1/2″ | 1 1/2″ 2″ 2 1/2″ 3″ | 101.6 | 48.3 60.3 73.0 88.9 | 95 | 79 83 89 92 |

| 4″ | 1 1/2″ 2″ 2 1/2″ 3″ 3 1/2″ | 114.3 | 48.3 60.3 73.0 88.9 101.6 | 105 | 86 89 95 98 102 |

| 5″ | 2″ 2 1/2″ 3″ 3 1/2″ 4″ | 141.3 | 60.3 73.0 88.9 101.6 114.3 | 124 | 105 108 111 114 117 |

| 6″ | 2 1/2″ 3″ 3 1/2″ 4″ 5 | 168.3 | 73.0 88.9 101.6 114.3 141.3 | 143 | 121 124 127 130 137 |

| 8″ | 3 1/2″ 4″ 5″ 6″ | 219.1 | 101.6 114.3 141.3 168.3 | 178 | 152 156 162 168 |

| 10″ | 4″ 5″ 6″ 8″ | 273.0 | 114.3 141.3 168.3 219.1 | 216 | 184 191 194 203 |

| 12″ | 5″ 6″ 8″ 10″ | 323.8 | 141.3 168.3 219.1 273.0 | 254 | 216 219 229 241 |

| 14″ | 6″ 8″ 10″ 12″ | 355.6 | 168.3 219.1 273.0 323.8 | 279 | 238 248 257 270 |

| 16″ | 6″ 8″ 10″ 12″ 14″ | 406.4 | 168.3 219.1 273.0 323.8 355.6 | 305 | 264 273 283 295 305 |

| 18″ | 8″ 10″ 12″ 14″ 16″ | 457.0 | 219.1 273.0 323.8 355.6 406.4 | 343 | 298 308 321 330 330 |

| 20″ | 8″ 10″ 12″ 14″ 16″ 18″ | 508.0 | 219.1 273.0 323.8 355.6 406.4 457.0 | 381 | 324 333 346 356 356 368 |

| 22″ | 10″ 12″ 14″ 16″ 18″ 20″ | 559.0 | 273.0 323.8 355.6 406.4 457.0 508.0 | 419 | 359 371 381 381 394 406 |

| 24″ | 10″ 12″ 14″ 16″ 18″ 20″ 22″ | 610.0 | 273.0 323.8 355.6 406.4 457.0 508.0 559.0 | 432 | 384 397 406 406 419 432 432 |

The dimensions are in millimeters

Source : ASME B16.9 – 2007

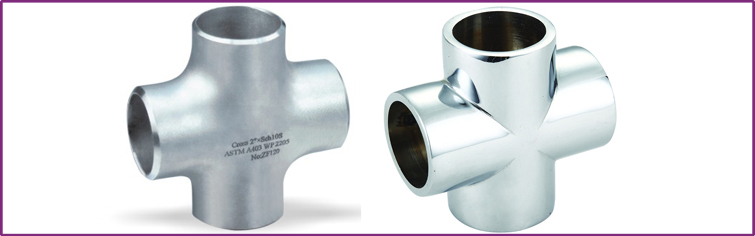

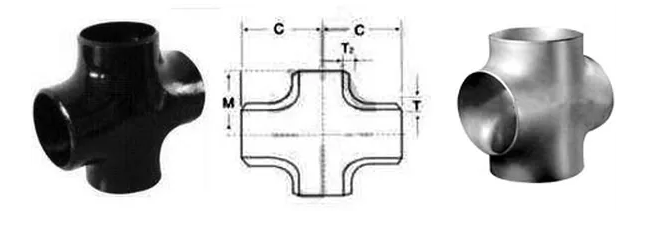

EQUAL CROSS

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

| Nominal Pipe Size (NPS) | DN | Outside Diameter at Bevel | Center- to-End | |

Run.C | Outlet. M[Notes(1) and (2)] | |||

| 1/2 | 15 | 21.3 | 25 | 25 |

| 3/4 | 20 | 26.7 | 29 | 29 |

| 1 | 25 | 33.4 | 38 | 38 |

| 1-1/4 | 32 | 42.2 | 48 | 48 |

| 1-1/2 | 40 | 48.3 | 57 | 57 |

| 2 | 50 | 60.3 | 64 | 64 |

| 2-1/2 | 65 | 73.0 | 76 | 76 |

| 3 | 80 | 88.9 | 86 | 86 |

| 3-1/2 | 90 | 101.6 | 95 | 95 |

| 4 | 100 | 114.3 | 105 | 105 |

| 5 | 125 | 141.3 | 124 | 124 |

| 6 | 150 | 168.3 | 143 | 143 |

| 8 | 200 | 219.1 | 178 | 178 |

| 10 | 250 | 273.0 | 216 | 216 |

| 12 | 300 | 323.8 | 254 | 254 |

| 14 | 350 | 355.6 | 279 | 279 |

| 16 | 400 | 406.4 | 305 | 305 |

| 18 | 450 | 457 | 343 | 343 |

| 20 | 500 | 508 | 381 | 381 |

| 22 | 550 | 559 | 419 | 419 |

| 24 | 600 | 610 | 432 | 432 |

| 26 | 650 | 660 | 495 | 495 |

| 28 | 700 | 711 | 521 | 521 |

| 30 | 750 | 762 | 559 | 559 |

| 32 | 800 | 813 | 597 | 597 |

| 34 | 850 | 864 | 635 | 635 |

| 36 | 900 | 914 | 673 | 673 |

| 38 | 950 | 965 | 711 | 711 |

| 40 | 1000 | 1016 | 749 | 749 |

| 42 | 1050 | 1067 | 762 | 711 |

| 44 | 1100 | 1118 | 813 | 762 |

| 46 | 1150 | 1168 | 851 | 800 |

| 48 | 1200 | 1219 | 889 | 838 |

GENERAL NOTES: All dimensions are in millimeters.

(a). Outlet dimension M for NPS 26(DN 650) and large is recommended but not required.

(b). Dimensions applicable to crosses NPS 24(DN 600) and smaller.

REDUCING CROSS

| Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | 1/2” TO 36” (SEAMLESS UPTO 24”) (WELDED 8” TO 36” ) |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) – straight cross, reducing cross |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

| Nominal Diameter | Outside Diameter | Center to End | |||||

| D1 | D2 | ||||||

| DN | NPS | Series A | Series B | Series A | Series B | C | M |

| 15×15 | 1/2×1/2 | 21.3 | 18 | 21.3 | 18 | 25 | 25 |

| 15×10 | 1/2×3/8 | 21.3 | 18 | 17.3 | 14 | 25 | 25 |

| 15×8 | 1/2×1/4 | 21.3 | 18 | 13.7 | 10 | 25 | 25 |

| 20×20 | 3/4×3/4 | 26.9 | 25 | 26.9 | 25 | 29 | 29 |

| 20×15 | 3/4×1/2 | 26.9 | 25 | 21.3 | 18 | 29 | 29 |

| 20×10 | 3/4×3/8 | 26.9 | 25 | 17.3 | 14 | 29 | 29 |

| 25×25 | 1×1 | 33.7 | 32 | 33.7 | 32 | 38 | 38 |

| 25×20 | 1×3/4 | 33.7 | 32 | 26.9 | 25 | 38 | 38 |

| 25×15 | 1×1/2 | 33.7 | 32 | 21.3 | 18 | 38 | 38 |

| 32×32 | 1.1/4×1.1/4 | 42.4 | 38 | 42.4 | 38 | 48 | 48 |

| 32×25 | 1.1/4×1 | 42.4 | 38 | 33.7 | 32 | 48 | 48 |

| 32×20 | 1.1/4×3/4 | 42.4 | 38 | 26.9 | 25 | 48 | 48 |

| 32×15 | 1.1/4×1/2 | 42.4 | 38 | 21.3 | 18 | 48 | 48 |

| 40×40 | 1.1/2×1.1/2 | 48.3 | 45 | 48.3 | 45 | 57 | 57 |

| 40×32 | 1.1/2×1.1/4 | 48.3 | 45 | 42.4 | 38 | 57 | 57 |

| 40×25 | 1.1/2×1 | 48.3 | 45 | 33.7 | 32 | 57 | 57 |

| 40×20 | 1.1/2×3/4 | 48.3 | 45 | 26.9 | 25 | 57 | 57 |

| 40×15 | 1.1/2×1/2 | 48.3 | 45 | 21.3 | 18 | 57 | 57 |

| 50×50 | 2×2 | 60.3 | 57 | 60.3 | 57 | 64 | 64 |

| 50×40 | 2×1.1/2 | 60.3 | 57 | 48.3 | 45 | 64 | 60 |

| 50×32 | 2×1.1/4 | 60.3 | 57 | 42.4 | 38 | 64 | 57 |

| 50×25 | 2×1 | 60.3 | 57 | 33.7 | 32 | 64 | 51 |

| 50×20 | 2×3/4 | 60.3 | 57 | 26.9 | 25 | 64 | 44 |

| 65×65 | 2/1/2×2.1/2 | 73.0 | 76 | 73.0 | 76 | 76 | 76 |

| 65×50 | 2/1/2×2 | 73.0 | 76 | 60.3 | 57 | 76 | 70 |

| 65×40 | 2/1/2×1.1/2 | 73.0 | 76 | 48.3 | 45 | 76 | 67 |

| 65×32 | 2/1/2×1.1/4 | 73.0 | 76 | 42.4 | 38 | 76 | 64 |

| 65×25 | 2/1/2×1 | 73.0 | 76 | 33.7 | 32 | 76 | 57 |

| 80×80 | 3×3 | 88.9 | 89 | 88.9 | 89 | 86 | 86 |

| 80×65 | 3×2.1/2 | 88.9 | 89 | 73.0 | 76 | 86 | 83 |

| 80×50 | 3×2 | 88.9 | 89 | 60.3 | 57 | 86 | 76 |

| 80×40 | 3×1.1/2 | 88.9 | 89 | 48.3 | 45 | 86 | 73 |

| 80×32 | 3×1.1/4 | 88.9 | 89 | 42.4 | 38 | 86 | 70 |

| 90×90 | 3.1/2×3.1/2 | 101.6 | – | 101.6 | – | 95 | 95 |